While the older machine may still work just fine, it may be time for an upgrade, just the same.The CNC router has served the business well, turning out thousands of sign components over the years, maybe even for a decade or two.

数控切割机在过去的几年、甚至十几二十年里,很好的服务于标识行业,生产了不计其数的标识部件。虽然旧的机器可能仍在正常的工作,但也是时候进行升级了。

Like any technology, however, there has been a product enhancement evolution. While the older machine may still work just fine, it may be time for an upgrade, just the same. The newest versions of CNC routers feature hybrid technology that offer versatility, consistent quality and more productivity. Those capabilities go right to the bottom line.

和其他科技一样,数控切割机的产品也在不断的改进与发展。虽然旧的机器仍然能够正常运转,但已经不是当前最先进的生产力。最新的数控切割机采用混合技术,拥有多样化的功能、稳定的质量和更高的生产效率。在标识行业的“Z世代”,这些能力是最重要的。

CNC technology in the sign making industry

数控技术在标识行业大显身手

CNC routers are an integral part of many sign shops' asset inventory, alongside digital printers and sign stock coating systems. If they don't have their own CNC router, sign makers may rely on a job shop that does use them. Letters for signage cut out by hand 20 years or more ago is a quaint memory for many, replaced by the quality and consistency of the digitally programmed router. But is it time for an upgrade? Have sign making competitors that already made the investment in newer machines been able to achieve a higher level of productivity - a function of shorter lead times and sharpened pencils when it comes to quoting prices?

数控切割机一般都在标识生产商的资产清单上占据大头,此外就是数码打印机和标识喷涂系统。如果生产商们没有自己的切割机,就会依赖于其他的切割机拥有者。对于大多数人而言,二十多年以前或者更早的时候,依靠手工剪裁标识只是一段古老的记忆了,数控切割机稳定的生产质量和产品一致性早已将它取而代之。

那么现在又到了更新换代的时候了吗?那些已经在新机器上投入资金的生产商们是否真的达到了更高效的生产水平,让其在竞标报价时足以缩短交货时间,减少所需资金?

What is "fit for purpose?"

符合下列情况,就去“买买买”吧

When the discussion about equipment replacement arises, start with one basic question: is the CNC router still fit for purpose? Some of the older CNC routers still in use have been custom-crafted in house by the sign shop and are more geared toward cutting a particular type of material. That doesn't always work in today's world, where there is a plethora of materials being used in sign manufacturing, often driven by customer demand, fueled perhaps by what they've seen in a trade magazine. In this environment, here are a few points to consider:

更换新设备,一定要考虑到旧设备是否可以继续服役。目前仍在使用的年代较久的数控切割机,有些是标识生产商们进行定制的,它们会更适合切割某些特殊的材料。但这只是特殊情况,在当今世界标识的制造使用着大量不同的材料,客户会从他们的需求出发,或是在行业杂志的推荐里进行选择,再交付标识公司制作。在这种环境下,有以下7点需要考虑:

1.Older CNC routers may not be as reliable, durable and accurate enough to be used with today's variety of sign stock.

1.较老的切割机是否依然可靠、耐用和准确,能够适用于今天的标识产品;

2.Previous generation CNC machines are much slower during cutting and scoring operations than the newer breed, which affects the bottom line. Today's CNC routers work at higher speeds and produce parts with smoother edges in many cases, meaning fewer post-routing finishing operations.

2.前代的数控机器从编程到切割都比新一代机器要慢的多,这触犯了生产的大忌。今天的数控切割机工作速度更快,大多数时候生产的标识边缘很光滑,这意味着更少的后道加工操作,缩短了整体的生产时间;

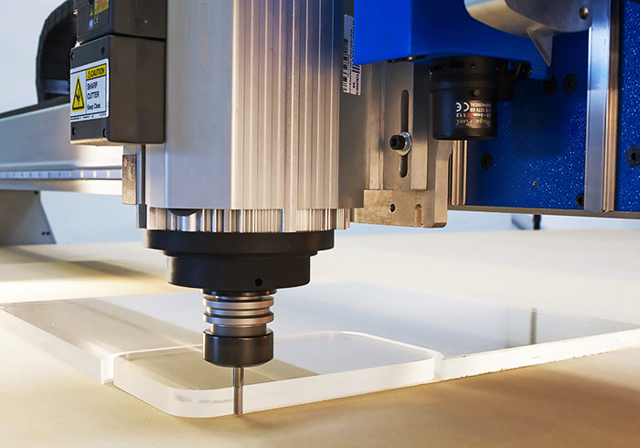

3.Older machines require more passes, maybe three or more, to cut through an acrylic sign stock cleanly. With today's CNC technology, generally the cut can be done in one pass, at a much higher speed. Improvements in extraction methods to remove debris from the router path has much to do with that significant change.

3.旧的切割机需要反复切割,也许要三次以上才能将亚克力材质的标识切割整齐。如果使用当前的数控技术,通常一遍就可以完成达标的切割,速度要快得多。这要归功于切割机算法的提升;

4.Employees might be spending an inordinate amount of time making repairs to keep an older CNC router in operation. Is anyone tracking those hours? Is cleanup time after taking pieces off the routing table piling up? To satisfy end user demands, the goal for CNC router manufacturers is to remove as much labor as possible from the operation of those machines.

4.当前数控切割机制造商的目标是尽可能避免机器故障,减少员工维修的劳动,以满足终端用户的需求。有人计算过为了让一台旧切割机能够正常工作,员工维修它所浪费的时间吗?这显然会大大的占用掉正常工作的资源;

5.Look at the competition. When quoting a particularly complex job and competing against other production sign shops, are they using the latest CNC router technology, and does that provide them with an advantage?

5.注意观察其他生产商,在竞标一个大项目时,他们所使用的新款数控切割机,是否为他们提供了优势;

6.Consider the expertise of others. Work closely with the CNC router manufacturer and distributor to assess the pros and cons of upgrading and investing in newer technology when the determination is that the current equipment is no longer fit for purpose.

6.参考专业数控设备制造商和经销商的评估意见,综合更新技术投资所产生的利弊,在确定当前设备的使用已不再划算时,就可以去更换新设备了;

7.Fit for purpose encompasses machines no longer compatible with today's software packages that deliver machine programs to the table. Much has changed over the past few decades, in large part based on feedback from those who purchased the first few generations of CNC routers. What were they looking for? What makes their routing and knife cutting operations more productive? What do they want from those machines? It's all about maximizing machine output without sacrificing quality.

7.数控切割机的软件在过去几十年发生了很大的变化,这些变化都是经由购买了第一代数控切割机的商家给出的反馈而不断改动的。通过这些改动,新一代的切割机操作起来更有效率,可以在不牺牲产品质量的前提下最大化机器的产量。

New may be better

“最新”也许就等于“最好”

Today's CNC technology means router/knife cutting combination machines and camera registration to align printed materials. Also, a combination router/knife system allows for many types of materials (from rigid to flexible) to be cut, providing more versatility on the shop floor. This efficiency can result in an increase in the number of clients that can be quoted. The words "we can't cut that," should not be part of a sign maker's vocabulary with today's newer technology. In addition, for smaller sign shops a combination machine is a money and space saver, freeing up the shop floor for other operations.

今天的数控技术,已经做到让切割机与摄像头相结合,可以准确识别出已印刷完成的部分。此外,可扩展的切割系统不论应对刚性或柔性的任何材料都可以完成操作,提供了更多的通用性。这种特性让可以发展的商业资源大大增加,在这个科技的时代,“we can’t cut that”(我们切不了这个)不应该存在于标识制造商的字典里。此外,对于较小的标识公司而言,这种综合性的机器也是一种节约成本,缩小生产空间的方式,可以为其他商业活动提供空间。

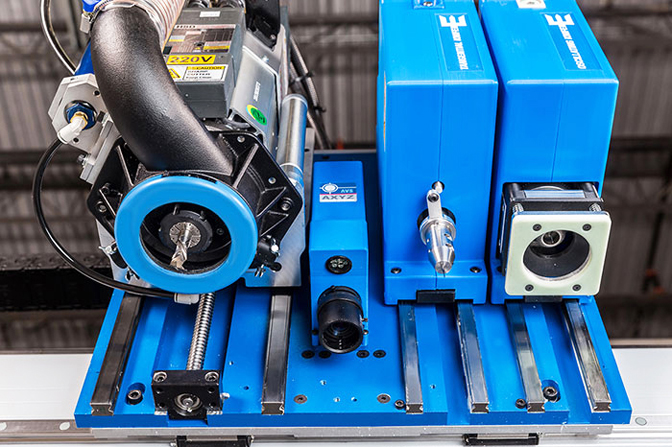

The newest technologies means direct drive servos (no belt or chain systems) for increased cutting accuracy and closer tolerances. Dual processing machines allow a single operator to load two jobs on a table, where each can be cut at the same time via automatic head separation, guided by the program. Automatic tool changers eliminate operator error, providing consistent quality as well. Localized head extraction removes debris and dust at the source, leaving a cleaner cut behind. That enhancement reduces the down time for additional cleaning between cuts.

直驱伺服系统(没有传动带或传动链)是最新的技术,可以提高切割的精度,产出更具一致性的公差。双核处理器允许操作人员在同一系统里装载两个作业程序,每个作业都可以在程序下自动分头同时进行切割。自动换刀具这一新功能,避免了操作人员的失误,为所有产品提供相同的质量。刀具头部近乎完全包裹,只留下一个清洁用的开口,最大限度避免碎片和灰尘的进入,减少了在更换切割产品时进行额外清洗的停机时间。

Now, controllers that can be updated via the internet with the latest software revisions provide for a multiple file import capability and nesting. Typically, older machines have less memory and can only store a reduced amount of digital information. In addition some of the newer CNC software packages are incompatible with older generation machines, which in some cases even harken back to the floppy disk era. That in itself may justify an upgrade, if files from customers cannot be received because the router's older controller can't accept the latest CAD programs.

现在的切割机还能提供多文件导入和嵌套功能,工程师们只需通过互联网下载最新的系统补丁来操作。但是对于旧机器来说,由于内存太少,可能容纳不了最新的系统。此外,一些较新的数控软件包与老一代机器并不兼容,有的老机器甚至还在用已经消失许久的软盘。如果因为旧机器不兼容最新的CAD程序,导致无法接收客户的文件,那么继续使用它会带来持续性的损失。

Updated vacuum systems can "zone" for the areas where the hold down on the routing table is needed. That maximizes the efficiency of the vacuum pump and can improve cut quality. Better cut quality of course reduces the need for manual post-routing cleanup operations that may be labor intensive and chip away at profitability. Some of the newer routers allow for multiple jobs and programs to be loaded on the same table. As the router cuts one job on the back end, other programs and the materials to be cut are loaded in a "batch mode" on the near side.

升级后的真空系统可以更好的固定住切割机所需要的工作区域,最大限度地提升真空泵地效率,保证切割质量。更好的切割质量减少了人工进行后道处理的需要,企业可以不再以劳动密集型的模式来赚取微薄利润。

最先进的一些切割机,可以在后端进行一个切割工作时,其他程序和要切割的材料以“批处理模式”在近端加载。

The verdict is in

“新”与“旧”高下立判

Sign making shops that have upgraded to the latest in CNC router technology do not seem to be having many episodes of buyer's remorse. On the contrary, they report a high degree of satisfaction for the capital improvement made. In fact, many testify that the new machine has paid for itself in a year or less, due to increased productivity and faster routing times that has increased shop capacity. In some cases, that means businesses are able to invest in a second new machine on a faster timetable as the first one gets closer to being paid off.

纵观已经更换新款数控切割机的标识生产商们,并没有出现一些“买家秀翻车”的情节,相反,他们对这种投资所带来的改善满意度很高。很多生产商表示,新机器在投入使用的一年内或是更短的时间,就已经收回了成本,这都是更快的切割时间和大大提升的生产效率所带来的。某些生产商甚至因为第一台机器所带来的丰厚回报,产生了尽快购置第二台新机器的想法。

Over the past several decades, many sign makers have upgraded their operations by investing in a CNC router and the related technology as they strive to remain competitive and increase productivity. The newer models on the market, featuring tweaks suggested over the years by end user clients, can be very inviting. In short, today's CNC router technology is about where computers, cell phones or automobiles are now in comparison to 20 years ago - vastly improved.

在过去的几十年里,为了保持竞争力和提高生产效率,许多标识生产商通过投资数控切割机产业及其相关的技术来对自己进行升级,因此市面上较新的机型,都拥有多年来大型企业级用户以自己的实际使用经验调整过的功能,这让新机器非常实用。简而言之,今天的数控切割技术就像电脑、手机、汽车一样,比之20年前都有质的飞跃。

Make no mistake however: this is a big investment, and the end user should make sure they are comfortable with their CNC technology supplier before taking the plunge. Also important: with today's higher end technology the need for thorough training and perhaps ongoing support is a must. The post-purchase services delivered by the CNC manufacturer and distributor may be just as important as buying the machine itself. Whether or not to upgrade to a new CNC router is often a six-figure capital decision that should be made with care and with an eye to the future.

不过,即使看到新型数控切割机的诸多好处,也请不要忘记,这同样是一项巨大的投资。在确定投入之前,标识生产商应该去考察数控切割机的供应商,是否具有完整的培训和持续的支持,这在今天的高端技术使用上是非常必要的。另外,关注机器的供应商提供的售后服务,这比购买机器本身还重要。

总之,更换一台新的数控切割机通常是一个至少投入六位数的重大决策,标识生产商们应该着眼未来、谨慎考虑。