When it comes to his craft, John Wardrope, president and CEO of Winnipeg-based plastics manufacturer Acryl Design, has always been keen on making huge moves and seeing where they take him.

当谈到温伯尔亚克力标识公司的设计总裁John Wardrope制作的手工艺术品时,他总是会让我们亲眼去看看这些工艺品。

“I started the business 35 years ago on a five dollar investment,” he says. “Since then, with no salespeople or out-marketing, our shop has grown and employs 25 people.”

John Wardrope说:“35年前,我用5美元开始投资了手工制作标识项目,那时候我们没有销售人员 ,也没有市场营销,但是我们的商店还是在发展壮大,并且雇用了25名员工。”

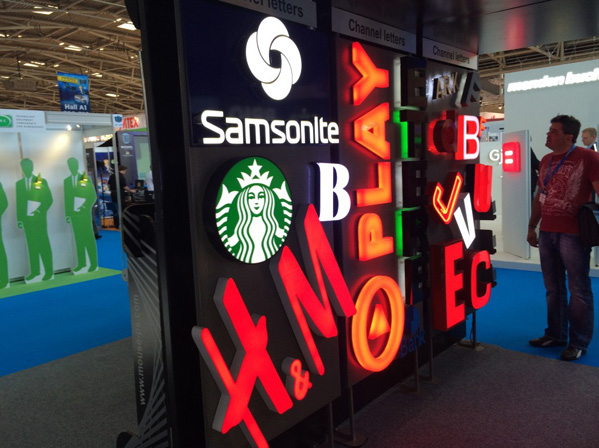

Acryl Design is equipped with all of the equipment needed for a spectacular sign shop: a computer numerical control (CNC) router, an ultraviolet-curing (UV-curing) light-emitting diode (LED) flatbed printer, a vacuum former, a roll-to-roll (R2R) printer, and more. However, despite having a loyal base of customers with ‘traditional’ signage needs, Wardrope does not consider his company to be a ‘sign shop’—or himself a ‘signmaker.’

现在,我们公司已经开始使用亚克力制作标识,还拥有计算机数控CNC雕刻机、紫外线固化喷墨机、LED光源、平板打印机、真空成型机、卷幅打印机等专业设备。尽管John Wardrope拥有许多客户,可以制作各种传统的标识,但是他并不认为公司已经是一个真正的标识制造公司,也没有认为自己是一个合格的标识制造者。

“We make signs, but that’s only about 20 per cent of what we do,” he explains. “My first business is making 3D objects. In other words, I am a custom fabricator. If somebody needs something made, I can make it! That’s the kind of work that drives me.”

他解释:“我们生产标识,只是占据公司业务的20%左右,而我们第一业务是3D打印。换句话说,我们是定制专业服务的公司,如果有人需要什么东西,我们可以马上去做,这才是我们公司真正的工作目标。”

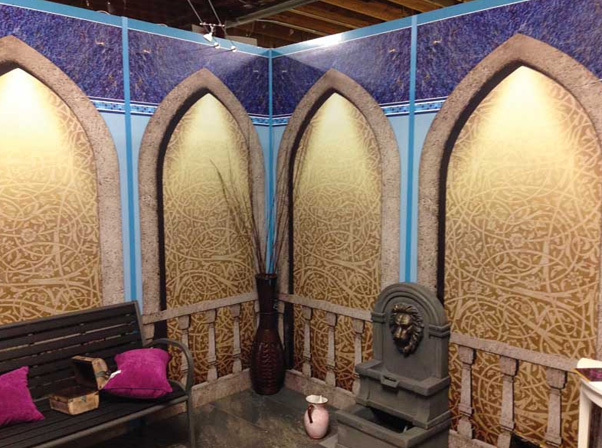

The rooms are made up of about 100 pre-fabricated sheets of UV signboard.

游戏屋的建筑结构由约100块定制的1.2×2.4米(4×8英尺)模组组成。

Crafty beginnings

巧妙的开端

Wardrope’s career in fabrication began in 1983 when he tried his hand at making costume jewellery out of acrylics and plastics. He rented a booth at a local Christmas craft show to sell his custom creations and soon found a market for his work.

1983年,John Wardrope第一次尝试用丙烯酸和塑料制作服装、珠宝标识,并且在当地租了一个展台,在圣诞节的时候展示了他制作的标识,很快他的作品就吸引了很多客户。

“The jewellery I created was eye-catching,” says Wardrope. “Pretty soon, people were approaching the booth to ask if I could fabricate other items. They were asking for menu holders, display cases—you name it.”

John Wardrope说:“我制作的珠宝标识非常引人注目,很快就有很多人来到展台问我是否可以制作其他的物品,比如菜单架、标识柜等。”

Wardrope took custom orders as they came in and taught himself to craft different items out of different types of plastic, including acrylic, polycarbonate, and polyethylene. His clients were impressed by his work and, from there, Acryl Design was born.

John Wardrope的客户说,对他的工作印象非常深刻。当John Wardrope接受了客户的订单后,他开始自己学习用不同类型的塑料制作不同的物品,包括丙烯酸、聚碳酸酯和聚乙烯,从此,亚克力设计就诞生了。

Growing with clients

与客户一起成长

As his client base grew, Wardrope expanded his services, purchasing advanced equipment and learning to use it on-site. In 1994, he invested in a CNC machine. He was not sure how to use it—and did not actually need it at the time—but figured the investment would pay off in the long run.

随着客户不断增多,John Wardrope购买了许多先进的设备,不断学习,逐渐地扩大了服务的范围。1994年,他就购买了一台数控机床,虽然他不知道怎么使用,而且当时也不需要使用,但是他从长远来考虑,认为这项投资会有回报。

Wardrope’s prediction was correct; in 1994, Acryl Design landed a contract with Imperial Tobacco Canada, which required plenty of digital printing and manufacturing on a variety of substrates, including polymetals, dye-bond, plexiglass, and double-sided cardboard.

John Wardrope的预测得到了应验。1994年,亚克力设计公司与加拿大帝国烟草公司签订了一份合同,需要亚克力公司在多种基板上打印大量的数字标识,包括多金属、染料粘合剂、有机玻璃和双面纸板。

“We were commissioned to do Imperial’s counter displays,” says Wardrope, “and, with the CNC router, we were able to imprint the company’s logos.”

John Wardrope表示:“自从有了CNC雕刻机,我们被烟草公司委托做标识柜时,我们就可以在成品上打印上公司的标识。”

From there, Acryl Design garnered attention from other big-name clients across the country. In 2000, the company started designing and manufacturing all of the displays for Soda Stream Canada. The project required printing for a range of applications, from video screens to airport displays.

从此,亚克力设计的标识吸引了全国各地客户的关注。2000年,John Wardrope标识公司为加拿大的Soda Stream公司设计了一系列标识,包括数字标识、导视标识以及景墙标识。

To keep up with the changing demands, Wardrope installed a UV-curing LED flatbed printer in his 1394-m2 (15,000-sf) facility.

为了满足不断变化的需求,John Wardrope在1394平方米(15000平方英尺)的空间中安装了一台紫外线固化LED平板打印机。

“Creating trade show booths for Soda Stream required a lot of printing,” he says. “We were printing graphics on 1.2 x 2.4-m (4 x 8-ft) foamboard, so purchasing a flatbed printer made sense.”

他补充说:“为Soda Stream公司制作的贸易展览摊位上的标识,需要打印大量的基材,比如在1.2×2.4米(4×8英尺)的泡沫板上打印图形,所以购买平板打印机是有意义的。”

Escaping convention

打破常规

In 2015, Wardrope received a question that piqued his interest.

2015年,John Wardrope收到了一个他非常兴趣的问题。

“One of our customers asked, ‘can you create an escape room that’s modular?’” he says. “I thought, ‘well, that’s different.’”

有一个客户问John Wardrope能否设计并制造出一个密室逃脱的游戏屋?John Wardrope回答:“哇!那肯定很棒!”

Often used as team-building exercises, escape rooms are interactive games where participants are required to solve riddles and challenges. They are usually hosted in existing buildings, with rooms furnished or altered to suit the game’s theme, but these modifications often present ambiguity in regards to safety codes and requirements.

密室逃脱游戏屋通常是指需要一个团队共同合作去挑战的游戏,要求参与者解开谜语,顺利逃脱。而各种提示标识被安装在游戏屋的建筑上,房间中还会布置许多适应游戏主题的景墙标识,但是这些标识是安装在游戏屋的通道中,而游戏通道的制作在安全规范要求方面存在歧义。

Wardrope opted to create a modular system that would allow designers to create customizable games, while also ensuring the safety of participants. The design makes it easy for the rooms to comply with building codes, as they come fitted with suitable building materials and electrical elements.

所以,John Wardrope选择在建筑之外的空间另外设计游戏屋,这样不仅符合建筑规范条例,还可以确保参与游戏者的安全,因为游戏屋配备了合适的建筑材料和发光标识。

“There are only 12 volts running through the system, and then it’s plugged into a 120-volt outlet,” explains Wardrope.

John Wardrope解释:“发光标识的电压只有12伏,非常安全。”

“The rooms, which are made up of about 100 pre-fabricated 1.2 x 2.4-m (4 x 8-ft) sheets of UV signboard, are clipped together via a custom-designed extrusion. The installation becomes like a building, with threaded rods and rails running through it. When the modular system is installed, the theme of the game is already applied and our client is able to furnish the set and further customize their game.”

游戏屋的建筑结构由约100块定制的1.2×2.4米(4×8英尺)模组组成,通过挤压的方式夹在一起,然后在使用螺纹杆稳定,这样整体空间就制作完成。接下来,客户就可以根据人们的需要制定游戏主题标识。

When shipped, the rooms are comprised of four skids of UV signboard, totalling 5443 kg (12,000 lbs). Two games fit in a 16-m (53-ft) trailer.

制作完成的游戏主题标识需要装运到游戏屋中,其中有两个游戏主题标识只能用16米(53英尺)拖车。

“So far, we’ve shipped about 30 or 40 games to the U.S.,” says Wardrope. “All of the designs we create are compliant with local building codes, and are also compliant with the Americans with Disabilities Act (ADA).”

John Wardrope说:“到目前为止,我们已经向美国运送了30到40款的游戏主题标识,而且我们制作的所有标识都符合当地建筑规范,也符合美国残疾人法(ADA)”

The Soda Stream projects required printing for a range of applications.

Soda Stream项目需要打印大量的标识。

Beyond the sign

不仅仅是一个标识

In early 2018, a Vancouver-based group asked Wardrope if he would be able to fabricate a specialty booth for an upcoming trade show. The client was looking for a functional, synthetic skating rink where attendees would be able to skate around.

2018年,温哥华一家溜冰公司找到John Wardrope,希望他们能为溜冰场即将到来的贸易展览制作一个专门的标识柜,并且以后他们可以免费溜冰。

“It was a fundraising booth,” explains Wardrope. “The client wanted to include a remote-controlled, digital scoreboard overhead to keep track of how many pounds of food had been donated.”

John Wardrope解释:“这个标识柜是一个募捐摊位,客户希望在增加一个远程控制的数字显示屏,为了记录有多少人募捐。”

The installation, which had to be durable enough to survive four days on the showroom floor, was printed and manufactured over three-and-a-half weeks at Acryl Design’s facility before being transported in a truck to the expo in British Columbia. The client’s team assembled the 4.8- x 15-m (15- x 50-ft) booth within eight hours.

因此,这个标识柜必须足够耐用,可以在展示厅中存放很久。所以John Wardrope标识公司用卡车运输标识柜到展示厅之前,已经在亚克力公司的工厂里制作了很久,标识团队还要在贸易展览前8小时内组装完成4.8-x 15-m(15-x 50 ft)的展位标识柜。

“We constructed the entire booth and manufactured every element,” says Wardrope. “We printed the synthetic ice, the crowd—everything.”

John Wardrope表示:“我们制作标识柜的每一个元件,都是仿制溜冰场,让标识柜与溜冰场场地融合。”

Acryl Design’s synthetic skating rink included a remote-controlled, digital scoreboard.

亚克力设计公司的溜冰场标识柜包括一个遥控的数字显示屏。

Next adventure

下一次奇遇

Now semi-retired, Wardrope intends to scale down his business and focus on projects that most interest him. Specifically, with the assistance of an electronics engineer, he has started developing new and innovative electronics, all of which have been approved by the Federal Communications Commission (FCC).

现在,John Wardrope已经是半退休的状态,所以他打算缩减公司业务规模,专注于制作他最感兴趣的项目。因此,在一位电子工程师的协助下,他开始开发新的电子产品领域,而且这些项目已经通过了美国联邦通信委员会(FCC)的批准。

“Over the past few years, I learned how to code computer chips,” says Wardrope. “With this technology, I’ve started creating wireless, reactive props for our escape rooms. These can be programmed so when a participant moves an item, it affects something else in the room.”

John Wardrope说:“在过去的几年里,我学会了如何编码计算机芯片,通过这项技术,我在密室逃脱游戏屋中添加了无线反应的道具,通过这些程序,当参与者移动某个物件时,其他物品也会发生改变。”

“I use signmaking equipment to create my projects, but I don’t always classify it as such,” he adds. “It’s really not sign equipment; it’s printing on an object with an idea—whether it’s a sign or anything else.”

他补充道:“我虽然参与制作了许多的项目,但是我并不会将它们全部归为一类,因为这不是真正意思上的标识制作,仅仅只是在物体打印上一个标识而已。”