“Highly beneficial, these [retail] signs facilitate 80% of purchase decisions made in store at the time of sale. They are vital to persuading customers to take the plunge and make a purchase. A point-of-purchase sign or display from Signarama is an attractive – essentially silent, salesperson – that helps sell products and drive up sales.”

“这些零售标识有助于商店在销售时做出80%的购买决定,非常有益的是。它们对于说服顾客冒险购买至关重要。来自Signarama购买点的标识和展示是非常有吸引力的——它们就像是无声的销售人员,它有助于销售产品,并推动销售。”

—— Maggie Harlow, Signarama Downtown , Louisville, KY

——玛吉·哈洛,肯塔基州路易斯维尔市西格纳拉马市中心

Digital die cutting? Although the term often comes up in machine marketing chatter, today, the term “die cutting” is often misunderstood. For the record, Webster’s, a valid resource, says a “die,” in machine terms, is any of various tools or devices for imparting a desired shape, form or finish to a material. Notice it said a desired shape, connoting a singular apparatus, such as a cookie cutter for making bunny characters. Initially, die-cutting processes were used to shear low-density materials, with the first machine processes supposedly applied to cutting shoe leather pieces. Today, a die-cutting machine comprises a hydraulic-type press system that downwardly drives sharp-edged steel “dies” (again, think cookie cutters, but heavy-duty) to shear prefigured cutouts or imprints in softer materials (gaskets or soft metals). Although practical, these devices are not comparable to computer-based cutting routers or finishing machines – or a wide-format printer that includes a digital cutting device, but ad writers often confuse terms and systems, which can perplex a machine-knowledgeable buyer. So, to clarify, a die cutter is a dumb (one function) production machine that, once fitted with a steel die (you can change them out), shear-cuts the same pattern in a substrate – head gaskets for a Chevy 350 ci engine, for example – over and over and over again.

知道“数码模切”吗?虽然这个术语经常出现在机器营销的闲聊中,但今天,“模切”这个术语经常被误解。根据韦伯斯特词典,用机器术语来说,“模具”是一种工具或设备,用于给材料赋予所需的形状或表面处理。注意,它说的是一个“所需”的形状,这就意味着我们需要一个独特的设备,如饼干切割器,切出兔子形状的饼干。最初,模切工艺用于剪切低密度材料,所以这种机器工艺被认为适用于切割皮鞋件。今天,模切机包括一个液压式的压机系统,向下驱动锋利的钢“模具”(同样,想想饼干刀)来剪切预制的切口或在较软的材料(垫片或软金属)上的印迹。尽管实用,但这些设备无法与基于计算机的切割机或精加工机(或包含数字切割设备的宽幅打印机)相比,但广告商经常混淆术语和系统,这可能会让熟悉机器的买家感到困惑。因此,澄清一下,模切机是一种只有一个功能生产机器,一旦装上钢模(你可以把它们换掉),就会一遍又一遍地在基板上剪下同样的图案——比如雪佛兰350 发动机的垫片。

A digitally programmed, spindle-equipped flatbed or roll-to-roll cutting device, aka a router and/or digital “finisher,” when suitably equipped with a high-speed spindle and bit or laser-cutting device can be programmed to continuous-line cut any shape or shapes multiple times. (Many routers are equipped with a Z axis for vertical lift that can produce bevel cuts).

当适当地配备高速主轴和钻头或激光切割设备时,可编程连续线切割任意形状或形状多次。(许多切割机都配备了Z轴垂直升降,可以产生斜面切割)。

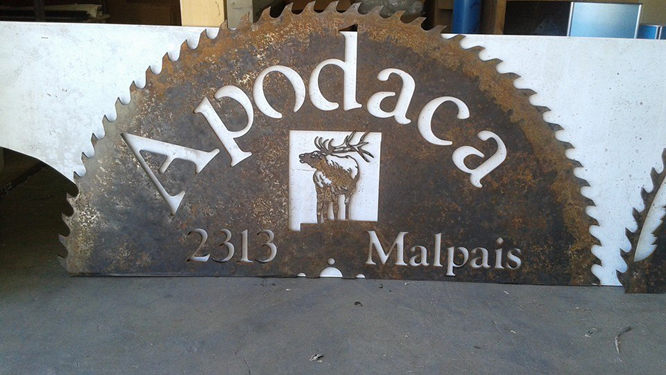

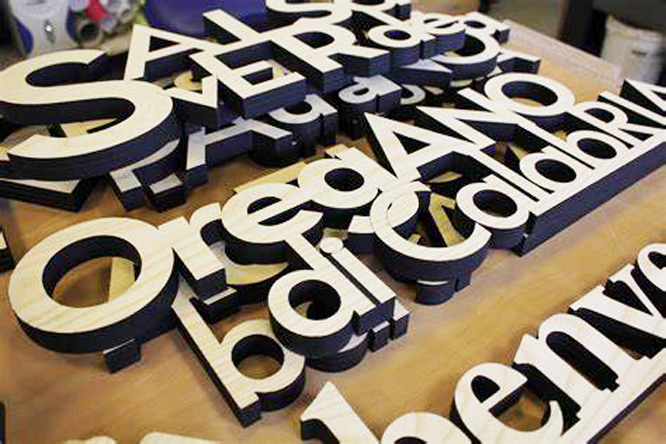

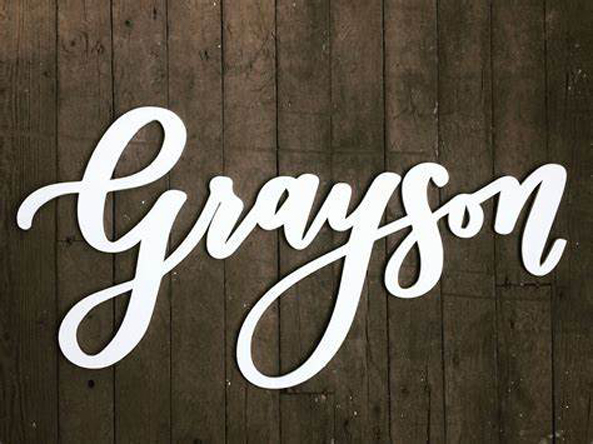

Contrast the two – routers and finishers – as if you were comparing a Toronto Maple Leafs goalie to a champion figure skater. Both have a skill, but it takes less than a minute watching to understand the difference. Therefore, if you’re fabricating and selling gaskets, beer glass coasters or die scores for Cheerios boxes, go for a die-cut shearing system; if you’re cutting channel letter faces, push-through or dimensional tea-shop signs, go for the router. But if your shop is inclined to digitally print and cut retail and tradeshow displays ad artwork – tire-sized cutouts of jelly donuts, for example – you’ll want a flatbed finisher.

对比一下这两个切割机和修整器——就好像你在比较多伦多枫叶队的守门员和花样滑冰冠军一样。两者都有技巧,但只需要不到一分钟的观察就能明白其中的区别。因此,如果你正在制作和销售垫圈、啤酒杯杯垫或麦圈包装盒的模切,那就采用模切系统;如果你正在切割发光字,或立体的茶馆标识,那就去使用切割机。但如果你的商店倾向于数码打印和切割零售和贸易展展示的广告作品——例如,轮胎大小的果冻甜甜圈——那么你会需要一个平板修整器的。

COMPARING FINISHERS AND ROUTERS

比较修整器程序和切割机

Many finishing machines are similar to cutting routers.

许多精加工设备类似于切割机。

The need for digital print “finishing” developed alongside digital print machines, especially the flatbed ones, because printmakers soon discovered the greater profits from selling the aforementioned digitally printed cutout standups.

对数字印刷“精加工”的需求随着数字印刷机器的发展而发展,尤其是平板印刷机器,因为印刷商很快发现,销售上述数字印刷裁剪产品的利润更高。

In a straightforward view, flatbed finishing cutters are light-duty cutting routers, and many manufacturers offer machines that will both cut and route. Primarily, many finishing machines are enormously similar to cutting routers and vice versa. In some cases, either can be equipped with spindle options that can govern a collet-mounted bit to cut metal, wood, rubber, fiber, cloth, paperboard, plastic, foam, sheet metal and other materials, including, of course, digitally printed cutout signage. Standups. The machine similarity is due to like components and buyer needs, plus finishing machines are often fabricated by the same companies that build and sell cutting routers.

从直观的角度看,平板精加工刀具是轻型的切割机,许多制造商提供的机器可以切割。首先,许多精加工机器与切割机极为相似,反之亦然。在某些情况下,任何一种都可以配备主轴选项,可以控制夹套钻头切割金属、木材、橡胶、纤维、布料、纸板、塑料、泡沫塑料、钣金和其他材料,当然包括数字打印的切割标识。机器的相似性是由于相似的组件和买家的需求,加上精加工机器通常是由制造和销售切割机的同一家公司制造的。

Each type comprises a table, gantry, spindle driver, collett, cutting tool(s), drive motors and tracking systems, and, hopefully, an onboard computer and digital feedback-control system. Your choices and options determine the type of work a machine should accomplish. For example, some finishing machines won’t cut soft metals, but will cut soft materials much faster than an ordinary router. Thus, your buying decision is based on the type and volume of work you plan to process. Let’s take one: Computerized Cutters’ Accu-Cut XP series routers are designed to cut material in two or three dimensions – X, Y; or X, Y and Z axes – and feature a virtual controller, an operator-control pendant, an auto tool-depth setter and a square rail system. Optional t-slot and vacuum hold-down systems are worth while, as is the auto tool changer. My favorite asset is that you can view the tool path as the part is being cut. Will it finish cut? Sure, because to some extent, all routers can finish cut – some better than others – depending upon your choice of machine type and spindle motor, and your production needs.

每一种类型包括一个工作台、龙门、主轴驱动器、夹头、刀具、驱动电机和跟踪系统,希望还包括一个机载计算机和数字反馈控制系统。您的选择就决定了机器应该完成的工作类型。例如,一些精加工机器不会切割软金属,但会比普通的切割机更快地切割软材料。因此,您的购买决策是基于您计划处理的工作的类型和数量。让我们来举一个例子:电脑切割机Accu-Cut XP系列切割机的设计目标是将材料切割成两到三个维度——X、Y;或者X轴,Y轴和Z轴。并具有一个虚拟控制器,一个操作控制吊坠,一个自动工具深度设置和一个方形轨道系统。安装t型槽和真空压紧系统是值得的,就像自动换刀器。我最青睐它们的原因是,您可以在切割工件时查看工具路径。当然,因为在某种程度上,所有的切割机都可以完成切割,这取决于您对机器类型和主轴电机的选择,以及您的生产需求。

As an example, because many choices are available, Esko’s Kongsberg X cutting tables feature its MultiCUT-HP tool that is equipped with a 3kw high-speed, water-cooled milling spindle that’s designed for extended duty cycles. It’s suited for cutting such materials as Plexiglas, acrylic, plastics, corrugated plastic, paper, labels, textiles, vinyl, vinyl banners, car wraps, foam board, rigid paperboard, fluted-core board, wood, aluminum-composite material, aluminum, MDF and more. Obviously, such a machine is suitable for regular signshop use and, in addition, it will production-cut standups and similar objects. Esko and many other manufacturers also offer similar and lighter machines.

举个例子,因为有很多选择,埃斯科的Kongsberg X切割台配备了多马力工具,配备了一个3kw的高速水冷铣削主轴,设计用于延长工作周期。适用于切割有机玻璃、丙烯酸树脂、塑料、波纹塑料、纸张、标签、纺织品、乙烯基、乙烯横幅、汽车包装、泡沫板、硬质纸板、凹槽芯板、木材、铝复合材料、铝、中密度纤维板等材料。很明显,这样的机器适合于正规的标识店使用,此外,它还会生产切割支柱和类似的物品。埃斯科和许多其他制造商也提供类似的更轻的机器。

In addition, note that several companies sell digital printer/cutters, such as Roland’s TrueVIS VG and SG Series printer/cutters, that digitally print and also contour cut various materials, including adhesive-backed vinyl, which can be applied as decals, individual sign letters, channel letter face outlines, partial car wraps – or installed on pre-cut media.

此外,仍然要注意几家公司销售数字打印机/刀具,如Roland TrueVIS VG和SG系列打印机/刀具,数码印刷轮廓切割各种材料,包括乙烯基,它可以用来制作贴花、单个字母标识、发光字的轮廓、汽车包装或安装在可以剪切的其他媒介。

LASER CUTTERS

激光切割机

Laser cutters can accomplish such unique work as smooth-edge cutting of Plexiglas – and they are versatile. Trotec Laser, for example, says its variously sized flatbed laser cutters will cut acrylic, foam, polystyrene, wood, MDF, Plexiglas, corrugated cardboard, polycarbonate film, textiles and – get this – carpet.

激光切割机可以完成一些独特的工作,比如对有机玻璃进行平滑的切割,而且它们用途广泛。例如,特罗泰克激光公司(Trotec Laser)表示,其各种尺寸的平板激光切割机将切割丙烯酸、泡沫塑料、聚苯乙烯、木材、中密度纤维板、有机玻璃、瓦楞纸板、聚碳酸酯薄膜、纺织品和地毯。

I’ve yet to see a sign cut from carpet, although I have seen digitally printed carpets at Walmart, ones with printed snapshots of pit bulls and poodles.

我还没有看到从地毯上剪下来的标识,不过我在沃尔玛(Walmart)看到过数码打印的地毯,上面印着比特犬和贵宾犬的照片。

BUYING DECISIONS

购买决定

To review the standup (aka cutouts) market, I visited Lane Pence, owner of FastSigns on Cincinnati’s Highland Avenue and found his shop stocked with cutout display samples; thus, I expected to hear him describe his digital finishing machine. Instead, I learned how his employee, Dave, is skilled at hand-cutting such signage. In addition, Lane spoke of his relationship with other signshops, and of a local woodshop that owns a cutting router, and how he subcontracts to such small businesses for jobs he prefers not to process. (This practice suggests that one regional signshop could buy a finisher and actively recruit digital print and cutout work from other shops.) Pence’s shop is nicely located in a retail area that’s near a light industrial zone, which gives him a good customer base as well as different types of fabricators who both buy signs and can provide unique services.

为了考察单口展位市场,我拜访了辛辛那提高地大道(Highland Avenue)上快捷广告招牌制作(Fast Signs)的店主莱恩•彭斯(Lane Pence),发现他的店里有大量的单个展位样品;因此,我希望听到他描述他的数字精加工机。相反,我了解到他的员工戴夫是如何熟练地手工切割这样的标识。此外,莱恩还谈到了他与其他标识店的关系,以及当地一家拥有切割路由器的木工店,以及他如何将自己不愿加工的工作分包给这些小企业。(这种做法表明,一个地区的标识店可以买一个可以精工细作的工人,并积极从其他店铺招募数码打印和裁剪作品。)彭斯的商店坐落在一个靠近轻工业园区的零售区域,这给了他一个良好的客户群,以及不同类型的制造商,他们既购买标识,又能提供独特的服务。

I had a similar conversation with Travis Neal at Signarama Carmel , in Carmel, IN, who said his shop hand cuts any cutout orders, including one they fabricated for the Indianapolis Park Department’s “Orchard in Bloom” garden show that featured standup cutouts of 1940s’ Hollywood-type images and lettering.

我和和特拉维斯·尼尔(Travis Neal)在印第安纳州卡梅尔市的(Signarama Carmel)进行了类似的交谈。尼尔说,他的店铺手工裁剪订单,包括他们为印第安纳波利斯公园部门(Indianapolis Park Department)的“盛开的果园”(Orchard in Bloom)花园展制作的订单。

FINISHING CONCLUSIONS

最后结论

Many signshops make regular use of digital finishing machines.

许多标识店经常使用数字精加工机。

In my opinion, if you’re production-processing finishing work, i.e., cutting out prints that are digitally imaged on lightweight rigid material, your primary decision concerns the cutting method – drag knife, tangential-knife cutting or spindle-based bit cutting – with the latter, along with laser systems, being the preferred method. A sharp bit running at super-high speeds cuts nicely. Next, of course, are table size and cutting speed, followed by the computer control systems (you’ll want correction feedback), safety factors and machine build. In use, finishing machines and routers are subjected to various forces, and unless the basic framework and the gantry are strong, the machine will eventually weaken, and this affects the cutting accuracy.

在我看来,如果你是生产加工的后处理工作,也就是说,你的主要决定是采用何种切割方法——拖刀、切刀或主轴钻头切割,后者和激光系统是首选的方法。锋利的钻头在超高速运行时切割得很好。当然,接下来是表的尺寸和切削速度,然后是计算机控制系统(您需要校正反馈)、安全因素和机器构造。在使用中,精加工机床和铣床受到各种力的作用,除非基础框架和龙门较强,否则机床最终会变弱,影响切削精度。

As with cutting routers and flatbed printers, a flatbed finishing device requires a steady table, a mirror-flat table top, a stable gantry and precise positioning of all the moving components. Gantry efficacy is affected by the span flexing, and the weight and torque of the spindle motor, plus gantry height and table weight support are important if you plan to cut more than flat or stacked images. You’ll also find different types of drive systems as well as diverse views for holding your material in place as cutting takes place.

与切割路由器和平板打印机一样,平板精加工设备需要一个稳定的工作台、一个镜面平面桌面、一个稳定的龙门和所有运动部件的精确定位。龙门效率受跨度弯曲的影响,而重量和扭矩的主轴电机,加上龙门高度和表的重量支持是重要的,如果你计划削减超过平面或堆叠的形象。您还将发现不同类型的驱动系统以及不同的视图,以保持您的材料在适当的地方进行切割。

Before buying, I recommend you inspect all parts of the unit. Crawl underneath to see if the table is solidly constructed and have the seller remove any cowlings, so you can see the welds and drive units. You want to see aircraft-quality fabrication methods, e.g., a solid table, quality motors and drive systems, and no loose-fitting parts or weld splatters. Over time, design weaknesses affect the machine’s tolerances and increase its aptitude for skewing. You don’t want that.

在购买之前,我建议你检查一下这台机器的所有部件。爬到桌子下面,看看桌子是否牢固,并让卖家移走所有的压盖,这样你就可以看到焊接和驱动装置。你想看到飞机质量的制造方法。例如,坚实的工作台,优质的电机和驱动系统,没有松动的配件或焊接飞溅。随着时间的推移,设计弱点影响机器的公差,并增加其倾向于倾斜。你不会想要你的机器出现任何故障,所以一定要做好检查。