IT’S ALL IN THE FINISH

投资终端设备——开启业务拓展新纪元

Cutting, routing and laminating remain key sign manufacturing paradigms but in addition have now enabled diversification from core manufacturing activities into new markets. These include the thriving digital print and cut, print wear and promotional products, labelling and packaging sectors that help create new revenue streams and lead to increased business and commensurate profitability for sign and display companies. Mike Connolly reports on some of the more impressive applications for cutting, routing and finishing systems as well as reviewing the latest product innovations.

切割机、雕刻机和层压机一直是制造标识的关键产品,现在,终端设备在标识制造中扮演的角色越来越重要,实现了从核心制造为出发点到呈现市场多样化的模式。终端设备的不断创新促使了数字印刷、服装印刷、标签和包装行业实现了利润最大化,成为了公司拓展业务和提升盈利能力的好帮手。近来,Mike Connolly公司推出了一些令人印象深刻的创新产品。

BOOSTING BUSINESS GROWTH AT B2B

在B2B模式上促进业务增长

Following installation of an AXYZ 6010 CNC router, Waltham Abbey, Essex-based B2B Exhibitions has been able to take on a huge amount of additional work that has contributed significantly to the company’s future growth prospects.

在B2B交易会上推出了AXYZ 6010雕刻机后,Waltham Abbey已经能够承担大量额外的工作,为公司未来前景做出重大贡献。

Established seven years ago as a single-person business by owner Greg Shire operating initially out of his garage, the rapid development of the company led toits relocation at a 3,500 square feet facility employing a full-time staff of five and using 20 additional part-time employees as business grew. B2B Exhibitions specialises in the bespoke production of exhibition stands, special event promotional signs and displays and shop fitting units. The AXYZ router is used for virtually all of the company’s output that includes, for example, melamine-faced boards for high-end exhibition stand elements and fabricated acrylic sheets for signs and displays.

公司已成立七年,最初,业主Greg Shire是从他的车库开始运营,在公司迅速发展的一段时间后,搬迁到一个3,500平方英尺的工厂,雇用了5名全职员工,从那以后,业务也开始增长起来。B2B交易会专门从事展台的定制生产、特别活动的标识制造以及商店装饰的制作的工作,AXYZ雕刻机几乎能应对公司大部分材料,包括高端展示架上的三聚氰胺面板以及标牌和显示器上的亚克力板。

Greg Shire commented: “Since installation of the AXYZ router we have been able to increase considerably the volume of work undertaken to the extent that it has been possible to set up a separate company to fully maximise the router’s huge potential.”

Greg Shire评论道:“自从推出了AXYZ雕刻机以来,我们能增加很多工作量,甚至可以设立一个单独的公司来专门制造雕刻机,发挥雕刻机为标识行业带来的巨大潜力。”

The AXYZ 6010 router has a processing area of 2159mm (width) x 3048mm (length). It incorporates the AXYZ Automatic Tool Change (ATC) facility and AXYZ Vision System (AVS) for optimum routing/cutting accuracy. Greg Shire added: “The router also includes special pop up pins on either side of the machine bed to ensure that successive sheets of material are always located in the same position on the bed.”

AXYZ 6010雕刻机的处理面积为2159mm(宽)×3048mm(长),这款产品集成了AXYZ的自动换刀(ATC)设备和AXYZ的视觉系统(AVS),能实现最佳的切割路线和精确度。此外,这款雕刻机还在机床两侧设置了特殊的弹出式针脚,以确保材料在机床上的位置相对固定。

In common with all AXYZ routers, the 6010 can be supplied with additional machining options. These include the AXYZ Auto Zone Management facility that ensures the material being processed is always held securely during the routing/cutting cycle and the latest A2MC machine control system. The A2MC has a massive 16GB of memory for program storage as well as providing network connectivity for error-free program transfer. A further optional production tool enhancement is the latest helical rack and pinion drive system featuring a multiple gear teeth configuration. This helps spread the workload more evenly and leads to greater cutting accuracy, faster throughput speeds, reduced material wastage and, ultimately, a longer than normal machine life.

同AXYZ雕刻机相比,AXYZ 6010雕刻机可提供加工选项,包括自动区域管理设施,能使正在处理的材料在机器控制系统中始终保持安全操作。A2MC机器控制系统拥有庞大的16GB内存,用于程序存储,还能提供程序传输的网络连接。这款雕刻机的创新在于增强了生产工具的性能,并配置了具有多齿轮的螺旋齿条和小齿轮的驱动系统,有助于更均匀地扩展工作面,从而提高切割精度,加快生产速度,减少材料浪费,延长机器的寿命。

Greg Shire concluded: “The entire structure was made from plywood cut by the router and featured a MDF-based frontage painted to simulate the appearance of brick. The router was also used to build the B2B Exhibitions’ main office that is also made of wood. It involved the processing of 150 sheets of 18mm hardwood ply over a period of five days.”

Greg Shire总结说:“AXYZ 6010雕刻机的整个结构是由胶合板制成的,采用了模拟砖的外观,可以在五天内处理好150张18毫米硬木地板,例如,像B2B展览公司办公室的木制地板。”

THE ACE PERFORMER

执行者ACE

Having installed a Zund S3 digital cutting table at its Northampton facility, Nene Packaging has greatly speeded up production with a commensurate increase in business growth and profitability.

近来,Nene Packaging公司制作出了一种新型的Zund S3数字切割机,它的出现加快了生产速度,同时促使了公司的业务增长和盈利能力的提升。

The company is an approved supplier of point-of-sale and floor display material to major supermarketssuch as Tesco and other retail outlets.

Nene Packaging公司是经过批准的地板材料供应商,主要供应于超市,如乐购等一些零售店。

Commenting on the reason for installing the Zund digital cutting table, Nene Packaging’s owner Rob Lugmayer said: “Our two existing CAD tables were slow and antiquated and limited to cutting out plain cardboard. To produce low-volume runs our customers needed to spend up to £200 on tooling costs, which made it impossible for smaller businesses.

Nene Packaging公司的业主Rob Lugmayer说:“我们安装Zund数字切割机,是因为现有的两张CAD表格非常的陈旧,仅限于切割普通纸板,客户常常需要花费高达200英镑的工具成本,才能进行低容量运行,这对于小型企业来说是具有挑战的。”

“We needed to upgrade in order to drive the company forward in the marketplace and, in March of this year, Zund UK distributor CMYUK supplied an ex-demonstration Zund S3 to replace one of the CAD tables. We also installed a new EFI VUTEk wide-format printer. This investment alleviated prohibitive tooling costs as well as speeding up the sample-making process and enabling short production runs.”

因此,我们需要升级,以推动公司在市场上的竞争力。今年3月份,英国分销商CMYUK还安装了一台新的EFI VUTEk宽幅打印机,这种投资减轻了过高的制造成本以及采样过程,缩短了生产周期。”

The Zund S3 includes a camera system that reads registration marks outside the main printing area and helps reduce material wastage. Like all Zund cutting tables, the S3 offers a modular tooling facility that enables automated processing of a wide range of materials up to a thickness of 25mm. This makes the machine ideal for the company’s point-of-sale and display sample production and its general brown-box work for engineering parts.

产品Zund S3带有一个摄像系统,可读取主要打印区域以外的注册标记,并有助于减少材料浪费的功能。和所有Zund系列切割机一样,Zund S3提供了一个模块化的模具设备,能够自动处理厚度达25mm的各种材料,该机器非常适用于一些样品的生产。

According to Rob Lugmeyer, it is likely that at a future date the remaining CAD cutter will also be replaced with a second Zund digital cutting table.

根据Rob Lugmeyer的说法,在未来,CAD刀具可能将被Zund数字切割机所替换。

MAKING A STAND

做一个大胆的假设

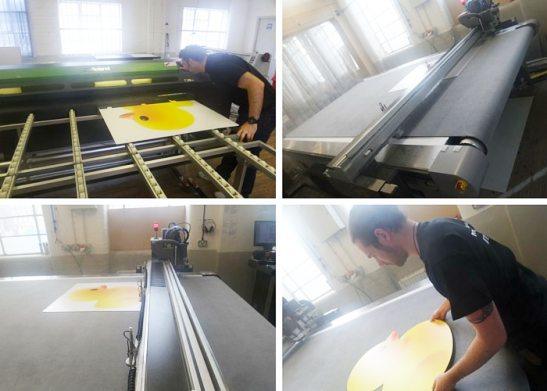

A DYSS X7 digital cutting table supplied by AG/CAD has enabled exhibition stand construction specialist Stand Innovations to set up a separate large-format printing company, whichhas resulted in new business and increased profitability.

AG / CAD公司提供的DYSS X7数字切割台,为公司建立了一个单独的印刷公司,从而拓展了新的业务,并提高了盈利能力。

Called StandOut Graphics, the new company specialises in the provision of bespoke digitally printed graphics and advertising solutions to support the exhibition stand construction work undertaken by Stand Innovations. Director Tom Noon commented: “We weren’t geared upfor creating graphics for our stand designs so these had to be contracted out at some considerable cost. So to solve the problem, we invested over £350,000 in specialist equipment including a large-format Jetrix printer and the DYSS X7 2230T digital cutting table and refurbished an adjacent unit so that we could reclaim the business being contracted out and target the business we were losing because we did not have the capacity to handle it. A year later, both objectives have been achieved, thanks in no small part to the new kit.”

StandOut Graphics是一家专门提供定制数字印刷图形和广告解决方案的新公司,支持Stand Innovations开展的所有展台搭建工作。公司的董事Tom Noon说:“为展位设计图形和标识,需要相当大的成本进行外包服务,为了解决这个问题,我们投入了35万以上的英镑在专业设备上,包括一台大型喷墨打印机和DYSS X7 2230T数字切割机,并成功收回了外包出去的业务,有了设备,我们自己有能力去处理一些业务了。”

Having opted for this particular cutting table and the Jetrix printer, StandOut Graphics is now able to undertake large-scale printing and cutting of a wide range of materials, including MDF, foamed board, aluminium composite sheet, Perspex, vinyl and glass.

使用了这种特殊的切割机和Jetrix打印机后,StandOut Graphics公司现在可以进行大规模的打印和切割工作,包括对MDF、发泡板,铝复合板、乙烯基和玻璃等各种材料的应用。

Tom Noon added: “The ability of the DYSS machine to precisely cut large non-uniform shapes with a perfect finish, based on a wide range of materials, has been a major benefit to both businesses.”

Tom Noon补充说:“DYSS机器的功能很强大,能够对各种材料精确地切割出想要的形状,。”

Key design features of the DYSS X7 include the K-Cut Vision system that intuitively identifies datum marks on each job and automatically calculates the required tool path. The machine claims 100 percent precision of cut on materials, even if their orientation to the machine bed is not parallel. Furthermore, the robust Superhead cutting head has the ability to accommodate six millimetre-diameter routing tools that can handle the thickest of materials. The cutting head also provides a threefold interchangeable production capability covering routing, knife cutting and creasing, thus reducing production and lead times on large projects.

产品DYSS X7有个专门用来设计的K-Cut Vision系统,可直观地识别每个标记,并自动计算所需的刀具路径,即便路径与机床方向不平行,机器也可以100%的精确进行切割。此外,坚固的Superhead切割头可以容纳6毫米直径的工具,提供路线、刀具和压痕三重互换的生产能力来处理非常厚的材料,从而缩短大型项目的生产时间。

Tom Toon concluded “The flexibility of the combined DYSS and Jetrix machines has yielded a healthy year one profit and helped to bring in new business .

Tom Toon总结道:“DYSS和Jetrix组合机器的灵活性已经为公司带来了一年的利润增长,帮助公司引进了新的业务。”

As a stand-alone operation, StandOut Graphics has a bright future and hasenabled us to enter new markets, such as the point-of-sale display sector.Practical Minds creates displays for the retail and exhibition markets, and serves leading brands including Harrods, Nike and Timberland. ”

作为一个独立的经营项目,它为StandOut Graphics公司在市场上赢得了竞争的优势,为零售和展览市场创造了更多的展示空间,同时在为Harrods、耐克和Timberland等领先品牌提供着优质的服务。”

Investment in a Versa Tech cutter has enabled retail design and printing specialist Practical Minds to bring in-house the cutting and finishing processes that previously were contracted out.

投资Versa Tech切割机这一举措,使印刷专家有了新的发现——切割和整理过程相当重要。

The Versa Tech cutter supplied by reseller Blackman and White features a 3000 x 2000mm processing bed and incorporates a multi-head cutter that can handle a wide range of disparate materials, including self-adhesive vinyl, foamed and aluminium composite sheets, acrylic and plastics, textiles, card and paper. The cutter is available in a choice of three different formats comprising flatbed, conveyor and laser-equipped models.

经销商Blackman和White提供的Versa Tech雕刻机采用了3000 x 2000mm的加工床,并配有多种切割头,可以处理各种不同的材料,包括自粘乙烯基、泡沫、铝复合片、丙烯酸、塑料、卡片和纸张等材料。切割器可选择三种不同的格式,包括平板、输送机和激光型。

A STEEP LEARNING EXPERIENCE

一次难忘的经验

Back in the late 1990’s, Peter Wilby and Max Wright, both seasoned professionals with vast experience in printing, were facing the realisation that, with advancing technology, their combined futures were looking extremely bleak.

早在上世纪九十年代末期,Peter Wilby和Max Wright就已经是经验丰富的印刷专业人士了,随着技术的进步,他们认识到,原有的终端设备在市场上的需求已经非常黯淡了。

Following a visit to the Franchise Show at the NEC, they decided to join a national franchise in the sign industry as this appeared to relate most closely to their past experience and enabled them to work out of a van and from home.

在NEC的特许经营会上,他们决定在标识行业加入一个带国有性质的经销权,这个想法的产生与他们过去的经验密切相关。

A couple of years later and with the franchisor unable to provide the promised support, Peter and Max opted to become independent and took up residence in their first unit on the present site. Peter Wilby explained: “In those early years, it was a steep learning curve but we have been able to build up sufficient local business and have never needed to advertise to secure this. Having seen a vertical panel saw in operation in one of the DIY sheds,our first machine acquisition was the new KF16 vertical panel saw from Sagetech that is designed primarily for the smaller business. The saw is used by the partnership to cut acrylic and aluminium composite sheets that hitherto would be on several days’ lead times from a sub-contractor, as well as timber-based materials.

几年后,特许人并没有提供相应的支持,Peter Wilby和Max Wright开始选择自己做,一直居住在现在的单位。Peter Wilby解释说:“在最开始的几年,我们经营像一个曲线一样不稳定,但能够建立起基本的本地业务,我们为些在标识行业中投入了大量的广告去宣传。在其中一个DIY棚内,我们看到一个垂直面板锯,我们制造的第一台设备是新型的KF16垂直面板锯,专为小型企业而设计的。”

The KF16 is just one of the four ranges of machines that are available from Sagetech. The Zapkut ZM range of saws is designed for lighter duties and starts with the budget-priced ZK8 portable unit. The saw handles a range of commonly used signmaking materials, while the heavier-duty Koolcut range of machines handle the thickest of materials.

KF16是Sagetech公司提供的四种机器之一。 另外,Zapkut ZM系列是为更轻型的任务设计的,可处理一系列常用的标识材料,而较重型的Koolcut系列机器可处理较厚的材料。

INCREASING PROFITS

利润增长

Creative cardboard engineering and print specialist, Anytech has recently installed a DYSS X5digital cutter, supplied by AG/CAD, at its Swindon headquarters in order to enhance its in-house capabilities and to expand the large format part of its business.

纸板创意工程和印刷专家Anytech最近在Swindon总部安装了由AG / CAD公司提供的DYSS X5数字切割机,这种产品能增强内部操作能力,还能为公司扩展相应的业务。

The new X5 machine is now working in-line with Anytech’s Xerox and Roland digital print devices to produce large format graphics and POS work, while also processing short-runs of digitally printed packaging without the need for the lengthy lead-times, set-up and other costs associated with conventional die-cutting. With innovative bespoke design a key part of its services, the company is also using the DYSS X5 to prototype new creations for its customers and to further extend its own product portfolio.

新型机器X5现在正在与Anytech公司制造的数字打印设备配合使用,以生产大幅面图形的工作,同时还可以处理简单的数字印刷包装,无需冗长的交货期。该公司使用产品DYSS X5为客户解决方案,凭借创新的定制设计和关键部分的优质服务,进一步扩展了自己的产品组合。

AG/CAD’s KASEMAKE CAD software was acquired as part of the same investment, enabling Anytech to produce imaginative structural designs speedily and efficiently and, in addition, the company has also found KASEMAKE’s 3D visualisation features to be invaluable when pitching to new clients and servicing existing customers, as, in a matter of moments, the software is able to render proposed designs as interactive 3D mock-ups, which can then be emailed for approval or proofing purposes.

AG / CAD公司的KASEMAKE CAD软件作为投资的一部分被收购,这样一来,Anytech公司能够快速有效地做出富有想像力的结构设计。此外,该公司还发现KASEMAKE CAD软件具有3D可视化功能,在某种程度上,软件能够将设计图呈现为交互式的3D模型,然后可以通过电子邮件发送给客户。

Chin Williams, the owner of Anytech, considered a variety of flatbed cutters before selecting the DYSS X5, which, he declared, was the clear winner, with the KASEMAKE package also adding a host of extra benefits.

Anytech公司的物主Chin Williams在选择使用产品DYSS X5之前,考虑过各种平板切割机,他宣称:“产品DYSS X5是明显的赢家,除此之外,KASEMAKE软件包也增加了许多额外的好处。”

Anytech has been growing steadily since its formation and, following the arrival of the DYSS X5, all of the company’s print finishing is now being handled automatically in-house, providing it with a real competitive edge when it comes to turnaround times and price.

Anytech公司自成立以来,一直稳步增长,随着平板切割机DYSS X5的到来,现在公司的印刷整理都是内部自动化处理,在周转时间和价格方面具有了真正的竞争优势。

Chin Williams concluded: “I am confident that our investment in equipment and software will enable us to increase company profits substantially, and don’t think that it’s unreasonable to aim for at least doubling our turnover within the next 12 months.”

Chin Williams总结说:“我有信心,我们对设备和软件的投资,将使我们公司的利润能够大幅度增加,当然,也不能夸大地说在未来一年内能增加一倍的营业额。”

DIGITAL DEADLINE HAS IT COVERED

全面实现数字化

A specialist in signmakingvehicle wrapping and wide-format digital printing, Leicestershire-based Digital Deadline has been in business since 2004. Included in the hardware installed at its premises is an Easymount Air laminator supplied by Vivid Laminating that replaced the previous GBC machine.

据一个做标识的专业人员介绍,自2004年开始,他们公司从车辆包装、宽幅数字印刷等方面投入运营,内部安装的硬件是由Vivid Laminating公司提供的Easymount Air层压机,取代了他们以前使用的GBC机器。

Having researched the marketplace for this replacement, Director Mark Brooks commented: “During research we were impressed by the frequent positive reviews of the Easymount Air laminator and the decision to purchase this particular machine was encouraged by our close links with Vivid Lamination. The GBC machine was not meeting our large-volume requirements and it needed to be replaced.”

主管Mark Brooks在做了市场调研后,有感而发:“在研究过程中,我们使用了Easymount Air层压机后,印象深刻,给出的都是积极的评价,购买这台机器最初的原因是,我们与Vivid Lamination公司已经合作多年了,而且GBC机器已经不再符合我们的大量需求,因此必须要更换。”

In addition to the new laminator, Digital Deadline also installed two Mimaki JV33 printers to support its wide-format work and to partner with the Easymount Air laminator. Mark Brooks continued: “We were given a demonstration of the laminator by the team at Vivid Lamination and were impressed by its performance and, in particular, by the fact that the laminator’s rollers can automatically detect the amount of pressure required for the laminating process. In addition to this, the rollers also stay completely level, regardless of the type of substrate being laminated.”

除了新的层压机,Digital Deadline公司还安装了两台Mimaki JV33打印机,以支持宽幅打印工作,并与Easymount Air层压机配合使用。Mark Brooks说道:“Vivid Lamination公司的团队演示了层压机的操作流程,我们非常看中这台机器的性能,特别是层压机辊子可以自动检测层压过程所需的压力,除此之外,无论层压的基板是什么类型,辊子都能保持水平状态。”

Mark Brooks was also impressed by the Easymount’s faster speed of 10 metres per minute and this was also a deciding factor in the purchase. He concluded: “For much of the time, we are laminating with full rolls of vinyl. With our previous laminator this would be a much slower process, but because the Easymount Air has the extra roll-to-roll unit, the whole process has become much easier and quicker and this has helped increase both our production levels and our profitability.”

这台层压机的工作速度为10米每分钟,因此,速度方面,也是购买这台机器的决定性因素。Mark Brooks得出结论:“在很多时候,我们使用的是全卷乙烯基材料,如果用我们之前的层压机进行操作,工作的效率非常低,而现在使用的Easymount Air层压机具有额外的卷对功能,整个过程变得容易快捷,有助于提高生产水平和盈利能力。”