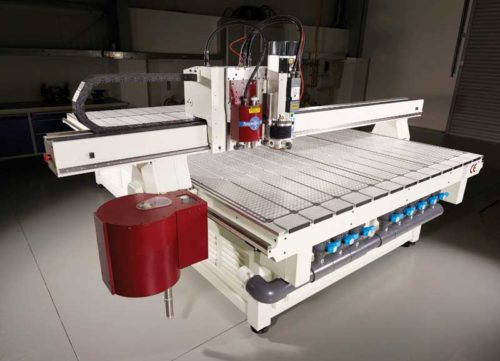

Many of today’s computer numerical control (CNC) routers have achieved the epitome of high-tech sophistication for sign shops focused on providing precise cutting and shaping to meet their customers’ demands. These machines—usually representing one of the largest investments a sign shop will ever make—are capable of 20 years of productivity.

现如今很多数控(CNC)设备已经具备复杂的高科技性能,帮助标识商铺专注于提供精准切割和成型技术以满足客户的需求。这些设备已有20年的生产性能,它们通常都是标识商铺最大的投资之一。

From a pure business perspective, the more regularly a router runs, the more income the shop can generate. Idle routers, on the other hand, negatively affect the company’s bottom line, to the consternation of its owner(s).

从纯商业的角度来看,数控设备运作越频繁,商铺的利润会越高。另一方面,闲置的设备也会对公司产生负面影响。

All too often, the reason for a router’s downtime has nothing to do with the design of the machine and everything to do with how it is being maintained. Every router comes with a recommended maintenance program, but while a sign shop’s employees may conscientiously try to follow it, they can still sometimes fall short.

通常情况下,数控设备停止运行的原因与机器的设计无关,而是与维修机器的方式有关。每台设备都有一个推荐性的维修方案,但是即使标识商铺的员工很认真地按照方案来维修,他们仍然会达不到要求。

Their difficulties cannot be brushed aside by simply attributing maintenance shortcomings to negligence. Usually, the smallest and seemingly most innocent oversights end up jeopardizing operations over the long term, perhaps due to the rush of the production schedule or a shortage of manpower on a particular day.

不能只将维修不足之处简单地归因于员工的粗心大意,还需要考虑到他们维修过程中遇到的困难。从长远来看,最小的、最不起眼的疏忽通常都会使得机器运作出现问题,可能是由于紧凑的生产计划或特定一天的劳力短缺。

Frankly, whatever the cause, the problem is the same. Everything from less-than-thorough lubrication to improper tooling in the spindle will play a role in shortening a router’s lifespan. And just because a machine continues to work efficiently the next day or the day after that, there is no guarantee against undesirable cumulative damage, which is certain to shorten its longevity.

坦白地说,无论是什么原因,最后出现的问题都是相同的。从不够完全润滑的主轴到不恰当工具的使用都会对缩短设备的运行周期。正因为设备在第二天还会持续高效地运作,因此会对设备造成二次伤害,进而缩短设备的使用寿命。

Avoiding the pitfalls of shortcuts

警惕保养陷阱

As mentioned, CNC routers should last up to 20 years if the manufacturer’s maintenance protocols are adhered to on a daily, weekly and monthly basis. They are designed and constructed for heavy-duty use. Their potential lifespan can be significantly reduced, however, when the recommendations are not followed.

如前所述,如果制造商可以坚持每天、每周、每月都按照维修协议给设备做维护,那么数控设备可以持续使用20年,它们是专门为重型应用而设计建造的。如果不遵循这些维护建议,就会缩短它们的潜在使用寿命。

Murphy’s Law, which states anything that can go wrong will at the worst possible moment, is certainly applicable to router operations. The last thing any shop needs is a machine sitting idle during a production run.

墨菲定律,即错误总是会出现在最糟糕的时刻,这同样适用于数控设备的操控。商铺需要考虑的最后一件事是,在生产运行期间的闲置设备。

Router downtime can certainly occur for reasons unrelated to routine maintenance, such as an electrical outage caused by extensive dust in the facility, but for the most part, such occurrences are rare. More commonly, improper maintenance is the problem, increasing the likelihood of an incident that is bound to increase the shop’s workforce and production costs.

数控设备停止运行的原因也可能与日常维护没有关系,例比如设备上的灰尘导致电气故障,但在大多数情况下,这样的事情是很罕见的。更常见的是不当维护问题,它会增加商铺的劳动力和生产成本。

“I’ve experienced what a lack of proper maintenance does,” says Andrew Kovach, shop supervisor at Barbican Architectural Products, a commercial and industrial lighting manufacturer in Fort Erie, Ont., that operates three routers. “If you don’t keep up on grease and oil, you’ll ruin the bearings and shut them down.”

巴比肯建筑产品是伊利堡一家商业和工业照明制造商,拥有三台数控设备,其主管安德鲁·科瓦奇说:“我遇到过缺少恰当维护带来的问题,如果你不持续加润滑油,那么设备的轴承就会损坏。”

As such, Kovach explains he follows the manufacturer’s recommendations to grease and oil the routers’ bearings every two weeks or, when the shop is especially busy, every 40 hours. He attributes adherence to maintenance for the continuing performance and reliability of Barbican’s three routers, one of which is 12 years old. The machines are used to cut metals and plastics in an environment Kovach describes as “dusty,” due to the presence of medium density fibreboard (MDF), other fixtures and shades, as Barbican maintains its manufactured hardware, lenses and shades on-site, but he points out router operations are rarely interrupted.

科瓦奇解释说,他会按照制造商的维护建议,每两周给数控设备的轴承加润滑油,或者当商铺工作量特别大时,每40小时都会加一次润滑油。他认为,巴比肯三台数控设备的持续性能和可靠性都归功于恰当的维护措施,其中一台已经用了12年。这些设备是在“落满灰尘的”环境中切割金属和塑料的,因为里面有中密度纤维板(MDF)、其他装置以及遮帘。巴比肯会在现场对硬件、透镜和遮帘进行维护,但是数控设备的运行几乎没有中断过。

“We have had minimal downtime and when we do, it’s usually because of electrical parts that we’ve been trained to replace,” he explains.

他解释说:“我们很少遇到过设备停止运行的情况,如果有这种情况,那通常是由于我们更换了它的电气部分。”

There may of course be times when the workload or a customer deadline can hamper adherence to a maintenance schedule, but given the expense of the equipment and the potential for long-term issues, such situations should be avoided if possible. Every maintenance requirement, especially daily lubrication, should be ensured by the shop’s management. There can be no shortcuts or ‘cutting corners’ allowed when it comes to the equipment that is the shop’s very lifeblood.

当然会有由于工作负载或客户期限妨碍到设备维护的情况,但是考虑到设备费用和潜在的长期问题,如果可能的话,应该避免这种情况。商铺应该确保能够做好每种维护需求,特别是日常润滑需求。设备关系到商铺的命脉,因此它的维护是没有捷径的,也是不可投机取巧的。

The process of routine router maintenance, for that matter, is not particularly time-consuming. Greasing the racks and bearings, by way of example, takes only a few minutes. Today’s router technology also simplifies the process, with automated internal logs to update users daily about issues as they are detected, documenting both their history and their resolution. The purpose of such features is to reduce the possibility of unexpected complications that could lead to downtime during a production run.

对于这个问题,常规设备维护流程并不是特别耗时。举个例子,在架子和轴承上加润滑油只需要几分钟。现如今的数控技术也简化了维护过程,可以自动更新检测用户的日常问题,记录其历史问题和解决方案。这些过程的目的是为了降低生产过程中导致设备停止运行的复杂状况。

Given all of the conditions associated with a busy production schedule, it can be easy for staff to miss a step or two. Fortunately, some advanced routers’ databases include an entire maintenance log—i.e. daily, weekly and monthly—to document the date and time of each action, thus verifying the prescribed schedule is being followed at all times. Router manufacturers can even access and send files of each day’s activity to the user at the shop or other facility.

在公司业务量比较大的情况下,员工很容易就忽略了一个或两个维护步骤。幸运的是,一些先进设备的维护数据需要包含每天、每周及每月完整的维护流程,记录每个环节的数据和时间,从而确保一直遵循着维护计划。数控设备制造商可以每天都给用户发送维护计划。

General guidelines

一般保养准则

Maintenance schedules tend to vary by specific machine and model, but the following five guidelines apply to all of them:

维护流程往往会随着特定设备和模型而有所变化,但是下面五个原则是通用的:

1. Ensure cleanliness.

1.确保清洁

It does not take long for CNC routers to get very dirty. Most of them operate in what can be considered a highly dusty environment, which visibly accentuates the need for cleanliness, but buildups of fluids or chips can also easily get into the bearings and controls. This is a sure recipe for problems if it is not corrected every day with cleaning.

数控设备用不了多久就会沾满灰尘。它们中的大多数都是在高度尘土飞扬的环境中运行的,所以很显然是需要清洁的,但是液体和碎片很容易进到轴承和操纵装置中。

Manufacturers generally recommend hand-sweeping of their machines. An air gun can also be used to keep substances away from the bearings. Another fairly standard recommendation is to lower the router’s air pressure during the cleaning process.

制造商通常建议人工清扫设备。气枪也可以保证灰尘不会进到轴承中。另一种相当中肯的建议是在清洁过程中降低设备的气压。

2. Change the filters.

2.更换过滤器

Just as clogged filters jeopardize the efficiency of an automobile’s engine, so too must a CNC router’s control box and vacuum pumps be changed on a regular basis, along with the filters that trap oil and water in the pneumatic lines.

正如堵塞的过滤器会危及汽车引擎的效率一样,数控设备的操纵箱和真空泵需要定期更换,连同留住油和水的过滤器也要更换。

As a rule of thumb, all filters should be checked weekly and changed as needed, but there is no standardized schedule. Rather, the frequency of the changes will vary, depending on the specific machine, the types of materials being cut and other environmental factors in the facility, such as dust and dirt.

作为经验法则,所有的过滤器都应该每周检测一次,根据需要进行更换,但是并没有标准的检测时间表。更换的频率会根据特定设备、切割材料的类型以及环境因素而改变。

3. Lubricate.

3.润滑

Despite their many parts, CNC routers do not require extensive lubrication, but breakdowns will be inevitable if the process is not followed as required. And should the failure to lubricate cause a malfunction, there is a real possibility of voiding the manufacturer’s warranty.

尽管数控设备的很多部分不需要润滑,但是如果没有按照准则进行润滑,那么出现故障是不可避免的。如果润滑过程出现问题,制造商的保修单就会失效。

Lubrication is so basic a step, no reminders should be necessary—but reminders help emphasize its importance. Bearings, pumps and oscillating knives all need regular lubrication and, again, the maintenance schedule will vary depending on the type of machine, the extent of its use and the environment around it.

润滑是很基础的步骤,不需要任何提醒,但是有提醒的话是强调它的重要性。轴承、水泵和振动刀都需要定期润滑。同样,维护计划表会根据设备类型、使用范围及周围环境而发生变化。

4. Keep the air supply clean.

4.保持干净的空气供给

Most CNC routers operate with pneumatic air, which has to be clean, dry and maintained at a steady pressure greater than 552 kPa (80 psi). With the incorrect specifications, damage to the machine is likely in a very short time frame, so the air pressure should be checked regularly.

大多数数控设备需要在干净、干燥和大于552千帕(80psi)的稳压气动环境中。在不恰当的环境中使用,设备可能会在很短的时间内损坏,因此还需要定期检测气压。

5. Provide safe and proper electrical power.

5.提供安全、适当的电力

As with any electrical machinery, the power supply to a CNC router must be sufficient and safely connected as required under any local power regulations.

和所有电气设备一样,数控设备的电源必须充足,且在符合任何地方电源规定的条件下连接安全。

Failure is most likely to occur in cases of poor electrical grounding, low voltage or insufficient capacity. Also, as is the case with other computer-operated mechanism, a spike in power can cause serious damage.

在电接地、低电压或电力不足的情况下,最有可能会出现问题。同时,与其他电脑操作机制一样,电压激增会造成严重破坏。

A detailed schedule

详细计划表

Each CNC router is accompanied by the manufacturer’s guide for daily and weekly preventive maintenance, including inspection forms, times for logging operating hours, general cleaning steps, air pressure readings and guidelines for oiling the oscillating knife, checking the pump oil and cleaning the cover nut threads.

每台数控设备都有制造商提供的每日及每周预防性维护计划,包括检查形式、操作时间记录、一般清洁步骤、空气压力读数以及振动刀加油指南、检查泵油、清洗螺母上的螺纹。

Monthly inspection forms, meanwhile, will cover greasing of racks, pinions and bearings, vacuum table gasket repairs—if needed—and cleaning of all filters.

与此同时,月度检查形式包括机盖、齿轮和轴承的润滑、真空表衬垫的修补以及清洗所有过滤器。

Finally, a form for biannual maintenance inspections will address the replacement of all filters, the testing and inspection of vacuum performance and the tightening of all timing belts and transmissions.

最后,一年两次的维护检查包括替换所有的过滤器、测试真空性能、拧紧所有同步齿带和传送装置。

Beyond the checklist

超出维护计划

Signmakers who use CNC routers have also learned there are times when a checklist is not enough to ensure smooth operations. Much like a vehicle, if the router does not sound just right, then additional analysis is necessary, even in cases where all of the checklist steps have been completed in a timely fashion.

使用数控设备的标识制造商都知道,有时候一个维护计划并不足以保证设备的正常运行。就像一辆车一样,如果车辆引擎的声音听起来不对劲,那么就需要进行额外的检查分析了,即使是在所有的检查事项都完成之后。

The emphasis on preventive maintenance should be the same throughout the useful life of the machine as it was at the beginning. Users will need a cleaning procedure and must make sure to remove every tool in the spindle.

设备在使用过程中的预防性维护应该与初次使用时同等重要。用户需要进行清洁程序,并且必须确保主轴上所有的工具都要清洗干净。

It is the shop owner’s responsibility to make sure his/her workforce clearly understands any shortcuts will be counterproductive and ultimately costly to the business. While routers are designed with long-term use in mind, they can quickly fail if any maintenance procedures are circumvented.

店主的责任就是确保其员工清楚地了解那些起反作用、成本高的捷径。虽然数控设备是设计为长期使用的,但是如果没有任何维护计划,它们很快就会出现故障。

The possibility of failure can also be due to other causes, such as improper operational procedures (e.g. when tools break because the right setup was not implemented) or when the machine’s movement is obstructed (which increases wear and tear and inevitably shortens its lifespan).

出现故障也可能是因为其他原因,例如不当操作过程(如没有正确操作设备导致工具损坏)或者设备被阻塞住(这样会增加设备磨损且缩短其使用寿命)。

The best way to ensure lengthy, productive CNC router operations and to reap the full benefits of the machine’s capabilities is to follow the manufacturer’s maintenance recommendations, but it may also be worthwhile to consider other service packages that are offered by the same manufacturer. This is because all machines, regardless of their sophistication and how thoroughly their maintenance plan is followed, will experience wear and tear over time. And if a machine is idled, then the sign shop is left with an expensive, non-functioning piece of equipment and a drain on its balance sheet.

确保数控设备长期、高效运行的最佳方式是按照制造商的维护建议进行设备维护,但是制造商提供的其他服务包也是值得考虑的。因为所有的设备,无论它们有多复杂、维护计划多彻底,都会随着时间的推移产生磨损。如果一台设备闲置,那么商铺得到的只是一个昂贵的、无用的设备以及资产负债表。