When it comes to signage applications, it all comes down to impact strength. Polycarbonate and acrylic plastics are two commonly used substrates for signage applications, and both are strong materials. They look basically identical to the untrained eye, and because of this, people often mistakenly people use the names interchangeably. But for those “in the know,” polycarbonates and acrylics are anything but the same. Knowing these differences will help to ensure the right material is chosen for the specific signage job at hand.

谈到标识制作材料的异同,归根结底就是其冲击强度的比较。聚碳酸酯采光板和亚克力塑料板是制作标识的两种常用基质,它们都是非常结实的材料。在非专业人士眼里,它们看起来没什么不同,正因为如此,人们总是弄错它们的名字。但是对于那些内行人士,聚碳酸酯采光板和亚克力板是绝不相同的。了解这些差异有助于确保特定标识项目采用合适的材料。

Although the two materials do share some similar properties, the key differences should be explored because signage applications—such as channel letters, cabinet signs, thermo- and vacuum-formed signs—have unique requirements. Variables that come into play for sign applications are strength, ease of fabrication, aesthetic qualities and durability.

虽然这两种材料有相似的属性,但是它们之间的关键性差异在于,不同的标识应用都有其独特的需求,例如槽形发光字、灯箱标识、热成型以及真空成型标识。标识应用中发挥作用的就是材料的强度、制造的容易度、美学风格和耐用性。

Toughness Comparisons

韧性比较

When comparing the toughness of polycarbonate and impact-modified acrylic (IMA), several ASTM (American Society for Testing and Materials) test methods are commonly used. In ASTM D-638, also known as the tensile strength test method, the material is held between two clamping jaws, and a device records the force required to stretch the sample to the breaking point. The higher the value of the force needed, the greater the strength of the sheet material. A side-by-side comparison of the ASTM D-638 data for polycarbonate and IMA shows that polycarbonate has a tensile strength of around 9,500 psi, while IMA’s tensile strength is approximately one-third less.

ASTM(美国材料测试学会)有几种常用的测试方法,用来比较聚碳酸酯采光板和改进冲击型亚克力板(IMA)的韧性。ASTM抗拉强度测试法D-638,是将材料放在两个夹钳之间,用一个设备来记录拉伸材料样品到断裂点所需的力。所需力的值越高,材料的韧性就越高。聚碳酸酯采光板和IMA的ASTM D-638比较数据显示,聚碳酸酯采光板的抗拉强度在9500psi,而IMA的抗拉强度约低于聚碳酸酯采光板的三分之一。

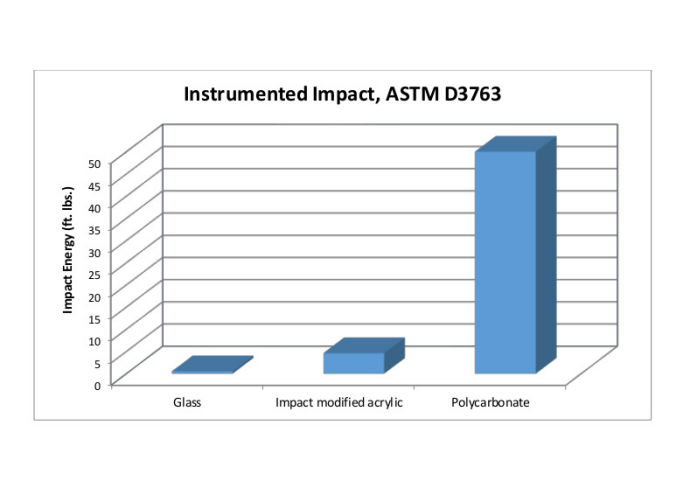

Another industry-standard strength test for plastic is the drop dart test (ASTM D-3763), which measures a material’s impact strength resistance. This test is performed under specific conditions where a 12.7-mm instrumented dart impactor is dropped from a distance of several feet and exerts 200 foot-pounds of force onto a 0.125-inch material sample.

另一种行业标准塑料韧性测试方法是下落标枪测试法(ASTM D-3763),它用来测量材料的抗冲击强度。该测试是在特定条件下,一个12.7mm的仪表化标枪冲击器从几英尺远的位置落下,在0.125英寸的材料样品上施加200尺磅的力。

This drop dart test shows that IMA has an impact resistance roughly 50 times that of glass, and polycarbonate’s impact resistance is even more impressive at more than 250 times the strength of glass (see Figure 1). Even though IMA is often substituted for polycarbonate, tests show that polycarbonate material far exceeds the toughness of IMA.

这种下落标枪测试法显示,IMA的抗冲击性约是玻璃的50倍,而聚碳酸酯采光板的抗冲击性更加令人印象深刻,是玻璃的250倍(见图一)。尽管IMA经常会被误认为是聚碳酸酯采光板,测试结果表明聚碳酸酯采光板的韧性远远超过IMA。

Fabrication Comparisons

制造容易度比较

While a material’s strength is definitely important, its ease of fabrication is also a critical component of sign making. Polycarbonate can be bent to a tight radius, 100 times the thickness (R=Tx100), without cracking or crazing. Acrylic, a more rigid thermoplastic, is limited to bending 180-200 times its thickness. Tighter bend radius adds stress to the acrylic sheet and may result in crazing or cracking of the material. Polycarbonate cuts and drills easily with little chance of it chipping or cracking unlike acrylic, due to its brittle nature.

材料的韧性绝对重要,同时制造的容易度也是标识制作的关键属性。聚碳酸酯采光板可以被弯成半径为其厚度的100倍(R=Tx100),并且不会有裂缝或破裂。硬性热塑性更高的亚克力板弯曲程度限制为其厚度的180-200倍。如果弯曲程度再大的话,就会增加对亚克力板材的压力,可能会导致龟裂。而聚碳酸酯采光板的脆性性质,使得它不像亚克力那样容易龟裂,在切割和钻孔时都比较容易。

Taking this one step further, we can examine the fabrication processes of the acrylic sheet when compared with polycarbonate. If there is a notch in the edge of a sheet as a result of sawing, routing or drilling, this notched area can be more sensitive to crack propagation. Cracking would make the finished sign no longer viable. In comparing ASTM D256—Notched Izod Comparison impact results—one sees that polycarbonate performance is 12 times that of IMA (see Figure 2). Polycarbonate, on the other hand, is easy to handle and virtually unbreakable.

由此更进一步说,我们可以检测出亚克力板和聚碳酸酯采光板制造过程的异同。如果板子边缘由于用锯、数控或钻孔留下切口时,那么有切口的位置对裂纹扩展更敏感。裂缝会使得已完成的标识不可再用。与ASTM D256缺口悬臂梁式冲击性比较结果相比,我们可以看到聚碳酸酯采光板的冲击性是IMA的12倍(见图二)。另一方面,聚碳酸酯采光板易于处理且牢不可破。

Aesthetic Qualities

美学风格

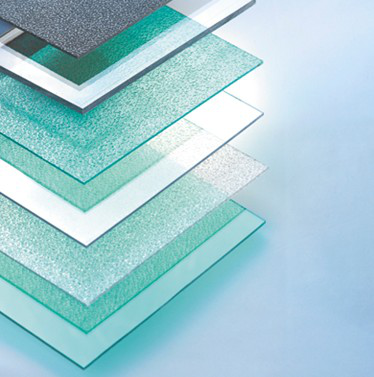

In addition to the material’s strength and durability properties, its aesthetic qualities are important to a sign’s success. Where a clear sheet product’s clarity is critical in glazing applications, it is less important in signage applications since most utilize vinyl graphics, screen prints or paint to achieve the desired look.

除了材料的韧性和耐用性的属性之外,其美学风格也是一个完美标识的重要特性。干净透明的产品特性对玻璃应用来说是至关重要的,但是它在标识应用中并没那么重要,因为大多数标识都是通过贴膜图文、屏幕喷印或涂料来达到期望中的外观。

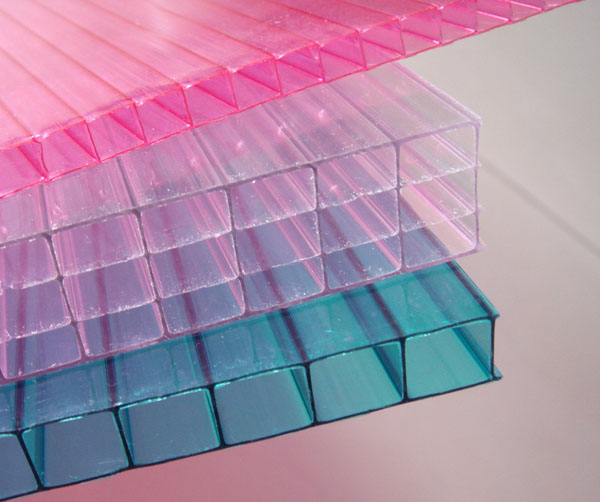

IMA and polycarbonate sheet and reel stock are available in standard industry colors – white, blue, red, yellow, orange and green. Some colors offer more than just a desirable hue. They perform an added function, as is the case with light diffusion. IMA and polycarbonate are both available as a white sheet that scatters light, thereby preventing visible hot spots from LEDs in typical flat and formed applications while maintaining high light diffusion. As with other grades, the light-diffusing sheets are easy to fabricate and form, and offer ultraviolet (UV) resistance to enhance long-term, outdoor weathering performance.

行业标准颜色对IMA和聚碳酸酯板材以及卷材都是可用的,白色、蓝色、红色、黄色、橙色和绿色。一些颜色不只有一种理想色度,它们可以带来额外的光线扩散效果。IMA和聚碳酸酯采光板都可以作为散射光线的白板,从而防止标识中的LED在保持高度光线分散的情况下,发出可见热点。与其他材料相比,光线扩散板材更易于制造和成型,并且其抗紫外线特性增强了长期户外风化性能。

UV-Resistance and Weathering

抗紫外线和风化性能

While UV resistance may enhance weathering performance, it does not make the materials immune to the effects of weathering altogether. As with all plastic materials, IMA and polycarbonate will degrade over time when exposed to UV rays and harsh environments. With the advent of newer manufacturing technologies, polycarbonate sheet material with excellent weathering performance properties is becoming available. This UV-enhanced product offers a 10-year protection warranty against UV degradation.

虽然抗紫外线可能会增强风化性能,但是它不会使材料免受风化作用的影响。和所有的塑料材料一样,IMA和聚碳酸酯采光板暴露在紫外线和恶劣的环境时,会随着时间的推移而降解。随着新型制造技术的开发,使得具有优良耐候性性能的聚碳酸酯板材成为可能。这种紫外线增强版产品,为抵抗紫外线退化提供了10年的保修期。

Harsh environments place weathering stress on plastics, and applications in severe weather environments require especially durable materials. Polycarbonate has a severe rating Class Zone 4—based on the ASTM E-1886 and ASTM E-330 standards—making it a good choice for use in areas prone to hurricanes and severe storms. Wind Zone 4 has basic wind speed greater than 160 mph. Numerous grades are listed in Miami Dade building codes as components of High Velocity Hurricane Zone, HVHZ. Polycarbonate has been tested as a component in a robust framing system and has passed the large missile impact standard per ASTM E-1886. IMA does not carry this rating.

恶劣环境会使得风化应力对塑料产生影响,所以在恶劣天气环境下的标识应用需要特别耐用的材料。根据ASTM E-1886和ASTM E-330标准,聚碳酸酯采光板分为严格的4等级区,可以依据飓风和严重的风暴天气条件来选择适用于该地区的材料。4级风区的基本风速超过每小时160英里。迈阿密戴德建筑规范列出多个材料等级,作为高速飓风区HVHZ的可用材料组件。在一个强健的框架体系下,聚碳酸酯采光板被当作一个组件进行测试,并且通过了标准大型导弹产生的影响,而IMA没有通过。

Chemical Resistance

耐化学性

Both acrylic and polycarbonate are generally easy to clean, but a plastic sheet’s chemical resistance varies based on the specific chemicals present. The location and use of a sign often dictates what chemicals it will be exposed to and which material provides better resistance. IMA has a better chemical resistance to certain substances, and polycarbonate is more resistant to others.

亚克力和聚碳酸酯采光板通常都易于清洁,但是塑料板的耐化学性会根据特定的化学物质而发生变化。标识的安装位置和用途通常决定了它会暴露在什么化学物质下、哪些材料能提供更好的抵抗力。IMA对特定基质有更高的耐化学性,而聚碳酸酯采光板对其他基质更有抵抗力。

The sheet’s chemical resistance comes into play even with routine cleaning. Care must be used when choosing the right cleaner for the job, as solvent cleaners can attack acrylic or polycarbonate substrates. A soft cloth with mild cleaners should be used for both materials with basic, mild soap and water being the best cleansing agents.

板材即使要定期清洁,它的耐化学性也会发挥作用。但是清洁时必须注意选择合适的清洁剂,因为溶剂清洗剂会损坏亚克力或聚碳酸酯基质。

Thermoformability

热成型性

Thermoforming sheet material is common in the sign industry. Both IMA and polycarbonate are easy to vacuum form using standard forming equipment. Prior to forming, polycarbonate must be dried, while drying is not necessary for IMA. However, polycarbonate has a shorter forming cycle due to faster cooling and part setup – allowing the formed part to be removed from the tool more quickly. Depending on the formed part design, automated vacuum forming equipment can achieve up to three times the throughput for polycarbonate over IMA.

热成型性板材在标识行业得到了普遍应用。使用标准成型设备可以很容易地将IMA和聚碳酸酯采光板做成真空形式。聚碳酸酯采光板在成型之前必须是干燥的,而IMA则无需干燥。然而,聚碳酸酯采光板由于较快的冷却装置,其成型周期较短,使得成型部分能较快地脱离设备。根据成型部分的设计,利用自动真空成型设备时,聚碳酸酯采光板的生产量是IMA的三倍。

Cost Comparisons

成本比较

While the features previously discussed should be the main factors influencing material selection, cost, although not the most important variable, is also in the mix. Besides the upfront cost of the material itself, additional costs may be incurred through shipping and also potential damage of a finished sign while it’s in transit. During shipping, a polycarbonate sign requires less packaging due to the sheet’s durability, thus reducing shipping claims incurred from breakage. These savings can go right to the bottom line.

前面讨论的特性是影响材料选择的主要因素,而成本,虽然不是最重要的可变因素,但也是必不可少的。除了材料本身的前期成本,额外的成本可能包含运输成本和运输途中成品标识的损坏所带来的成本。在运输期间,聚碳酸酯采光板标识由于板材的耐用性而无需复杂的包装,从而可以减少运输途中的损坏。

Visually stunning signs can be created with either IMA or polycarbonate, but the material’s inherent strength, ease of fabrication, aesthetic characteristics and durability influence the success of the end product. This makes material selection a crucial step in sign creation and underscores the need to know the differences between polycarbonate and IMA and how their selection will affect the finished sign.

用IMA或聚碳酸酯采光板都能做出视觉冲击力极强的标识,但是材料的固有强度、制造的容易度、美学特性和耐用性决定了最终产品能否成功。这使得材料选择成为标识创意的关键,强调了了解聚碳酸酯采光板和IMA差异的必要性,以及他们的选择会对最终的标识产生怎样的影响。