A few weeks ago we had a project to build a pole sign,all metal construction, in two units,with all radiuscorners. While there might be any number of ways to construct a non-electrical sign like this, I knew I would do a lot of the work myself, and it would be made of mostly pre-finished aluminum. If I could do it without welding at all, there would be no need prep, paint or powder coat. The factory finish on the aluminum could stay masked and unmarked, ready to install.

几周前,我们接到一个立杆标识的制作项目,全部由金属建造,并且标识的两个部分都是圆弧形。有很多种不同的方法去制作这样的标识,这个项目将通过很多步骤来完成,并且标识会主要使用已经处理的铝制金属。如果我能不用焊接将它封装成形的话,那就能省略油漆或者喷涂粉末之类的准备材料了。在工厂里把金属部件完成并保留保护膜不被刮痕,直接就可以安装。

Really,at least with the wire-fed gun we have ,I am not proficient at aluminum welding .But,I have done

fed gun we have, I am not proficient at aluminum welding. But, I have done a lot of sheet metal work, and have a 10’ break and some CNC equipment at my disposal. This sign would be riveted together, formed around geometric parts cut on a waterjet or router, formed basically by hand and with a brake, and built light enough to allow installation using my bucket with lift. No crane needed.

对于这个标识制作我还是挺有信心的,我有很多使用金属板材的加工经验,并且有一个10’制动工具和一套CNC的设备,这个标识我们可用切割机将铝材切割成几何部分,然后用铆钉固定,并使用制动钳成型将它们组合在一起。在这个过程中我尽可能地减轻它们的重量,以便于可以用卡车来运送安装,这样可以避免使用起重机。

I can’t say it went together as fast as I imagined it would in my mind, but there were no real problems, and the result was as good as I could expect. While there were several hundred rivets, no welding was needed and the sign was plenty strong. It would mount over an existing pole, and a steel extension to the existing sign pole was the only welded item on the job.

我不能确定它的制作过程跟我设想的进度一样,但我们确实没有遇到棘手的问题,就其结果而言,我还是非常满意的。虽然标识内部有几百个铆钉,但是它不仅没有被焊接而且标识还很坚固结实。将其安装在标识杆上以及标识杆的连接处是它唯一需要焊接的地方。

First, of course, there was a good bit of time designing the parts. Then it took an afternoon or so to cut all the pieces on a waterjet available at our other shop, WPC Services. On all the main pieces, small tabs were placed all around the edges, bent upward 90 degrees, and curved formers were riveted to these tabs to give the signs their shape.

首先,毋庸置疑的是我们花了很多的时间来思考这个设计的过程。然后,我们又花了一个下午的时间将铝材切割成我们想要的形状。在标识的全部主体部分,铝材边缘都留有突出的铝材板扣部分,并且被向上折弯90度,然后再用铆钉固定就可以得到我们想要的形状。

The top sign was a large circle about 54” in diameter and 16” thick. And the lower sign was approximately 3’ x 9’, with 8” radius corners, and the same thickness. Originally I had drawn the rectangular sign with 6” radius corners, following a design our client’s advertising agency had drawn up. But, I was determined to make all the parts in-house, with no painting or finishing, so the trim pieces or retainers would be made from silver anodized .040 aluminum would have to be formed to the radius corners of the sign. Through some experimentation early on, I determined this type of shop-made trim could be curved to a radius no smaller than 8” before it would kink when hand forming, so that was the radius we went with.

顶部的标识是一个直径有54英寸长,16英寸厚的圆形标识。底部的标识是一个3英尺 x 9英尺规格的长方形,厚度和顶部圆形标识一样,这个矩形的特殊之处在于它的边长的连接处不是直角而是8英寸的弧形。起初,我打算按照客户的设计用6英寸的弧度来处理矩形标识的直角部分,但我最终决定所有的制作过程都在室内,既不使用喷漆也不打算精雕细琢,所有的修饰和边框部分都可以用.040银色电镀铝来解决,电镀铝可以把标识的四边都做一个很好的包边修整。根据我早期的一些实验,我确定这些用来塑形的边框可以手动弯曲成不小于 8”的弧,所以,我们就采用了8”的弧处理矩形的直角处。

All of the sign parts except for the silver trim pieces were made from pre-finished .063 white aluminum sheets. No frame was made of anything other than that, so both signs involved were basically sheet metal creations.

全部标识的部件中除了银色的边框部分,都是使用已经处理好的.063的白色铝材。除了.063白色铝材没有应用任何其它的材料,因此两个标识都是使用金属板材创作。

The top sign, a simple circle shape, was made from two strips with tabs around the edges bent on a brake to 90 degrees, and the two pieces joined at the exact top and bottom quadrant of the circle. For each side of the sign, there were four radius formers of a quarter circle each that defined the shape of the circle. At the very last I made two “stringers” or stiffeners made of 1” x 1” aluminum tubing. These were put in at 90 degrees from each other to hold the circle shape exactly the same diameter north-south, and east-west.

顶部的标识是一个简单的圆形形状,是由两块长条铝材制作而成,并且长条铝材边缘都有被弯成90度的扣子。这两部分从头到尾的区域被连接在一起。在标识每一边四分之一圆的部分都使用弧形边条把标识固定成圆形的形状。在最后,我制作两根1”x1”正方形的铝制加强杆作支撑。这两条支撑杆被放置成90度成一个十字的形式支撑两边,使整个圆形标识从南到北,从东到西都有很好的加固,成为一个完美的圆形。

There were special parts designed for the exact top and bottom of the circle. The bottom joining piece reen-forced a circular cutout to accommodate the pipe that would come a few inches up through the bottom of the sign. Inside the sign, a steel tube extension was to be welded to the top of the existing pipe sign pole we were mounting the signs to, and that tube would fit a socket inside the sign at the top. The socket fit fairly loose, but there was a “bushing” made that fit the square tubing mast snuggly and the position of that bushing could be adjusted slightly to level the sign perfectly. The bushing would be attached with large rivets in place on the socket, locking the sign in place.

在圆形标识顶部和底部都做了一些特殊的设计。标识的底部被制作成可容纳几英寸长的管状立杆圆孔。标识的内部,会在原来标识的立杆上面安装焊接一个柱形的延伸部分。并且延伸部分会插入到标识顶部的插座上面。由于在插座部分会比较宽松,所以在延伸部分与插座之间会安装一个方形“管套”来固定标识的位置,并且使标识可做一些轻微的调整达到一个完美的状态。管套将被大铆钉与插座连接在一起,并固定标识的位置。

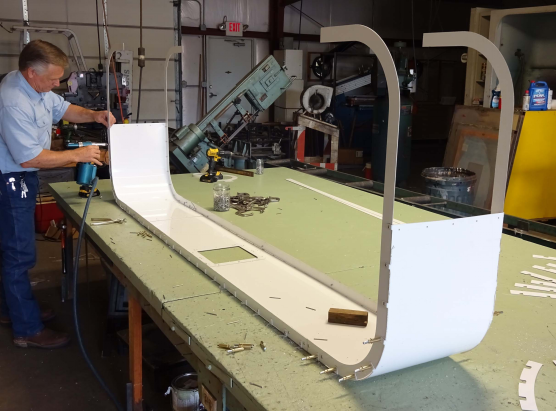

The lower sign, as the photos show, was put together by adjoining four main strips of sheet metal, again with 90 degree tabs all along the edges. Riveting these tabs to formers made from the same white .063 aluminum. Joining pieces at the top and bottom center provided cutouts for the sign pole to pass through. A ring of 1/8” steel was welded to the pipe in the field where the bottom of the sign was to stop and the sign would bolt to it. There were a couple of sheet metal pieces made to form an adjustable bushing at the top of the lower sign to lock it snuggly to the sign pole.

下面的标识像图片展示一样,通过四块主要的金属条与边缘弯成90度的板扣连接在一起。与板扣连接的边条同样是使用.063的铝金属。在标识顶部和底部的中间都制作了一个让标识管贯穿的切口。一个1/8”环状铁片被焊接在标识管上,并且标识底部可被固定和标识可以拴紧。这些金属的部件使标识的顶部可以被套住,底部又可以很自然的被固定。

The actual sign faces weren’t made until the sign structures were completely fabricated, and the exact shape and dimensions were confirmed. The round faces of the top sign were made from aluminum laminate covered with a digitally printed graphic, and the lower 3ft x 9ft faces were made from more pre-finished aluminum sheet, covered with a reverse graphic of blue hp vinyl. The cracks or seams at the edges of the faces had to be kept small since the satin silver aluminum retainer strips would have a very narrow lip of just about 5/16”, only enough to hide the seam and the small rivets that actually held the faces in place before the trim was installed.

在标识的结构框架制作和真实形状与尺寸被确认前,标识的实际模样都不能被制造。顶部的圆形标识是使用数字打印图像铝层覆盖版制作,而下面3英尺x9英尺标识的表面是使用覆盖反向图像蓝色hp背胶的已处理铝制材料制作。标识表面边缘部分要保持非常小的缝隙,因为银色缎面电镀铝边框条非常窄只有5/16”,只能仅仅的藏在缝隙里面,并且在边框安装之前小的铆钉需要固定在表面的地方。

The signs would be installed without faces in place. To make sure the 9’ long lower sign did not sag in the slightest amount and the faces would fit right back into pre-drilled rivet holes, a pair of formed aluminum “purlins” were installed on each side, making the sign even more rigid. These were screwed to vertical members made from light wall 1” x 1” aluminum tubing. Later, after the sign was in place on the sign pole and the faces were put back in place, each rivet hole lined up perfectly.

这个标识在没有表面的情况下也可以被安装。要确保9英尺长的底部标识不会滑落丝毫,并且标识表面可以嵌入已经钻好的铆钉孔,一对塑形的铝制“檩条”被安装在两侧使标识更加坚固。这些都是有1”x1”轻量铝制管材竖直的安装在标识内部做支撑。最后,在标识被放在标识杆上和表面被安装后,每一个铆钉孔都被完美的匹配。

Except for the top mast added to an existing sign pole, as intended, there was no other welding required on this job. But with all that drilling and riveting, the project seemed a little like putting an airplane together. One real similarity was the use of “clecos” as temporary rivets when fitting something together. These spring loaded re-usable fasteners are most often used in aircraft construction, but can come handy for sign making as well. And at less than $1 each (from Aircraft Spruce and Specialty) they areinexpensive enough to keep a set of them to fit 1/8” holes, and 3/16” holes for standard aluminum rivers.

除了在现有的标识杆上增加顶部的延伸部分,如预期的那样,整个项目并没有要焊接的地方。但是在所有钻孔和铆接的地方,这个项目更像把一架飞机组合在一起。一个真正相似性是当把一些部件连接在一起的时候,会使用“定位销”作为临时的铆钉。这种受载弹簧的重复加固通常是用在飞机制造上,但是同样可以使用在标识的手工制作。并且这种定位销每个的价格低于1美元,价格便宜以足以让你保存一套应用在1/8”和3/16”铝制铆钉孔。

The final components of this job were the shop-made retainer trim pieces that trimmed out both sign units nicely. Strips of satin silver anodized aluminum, .040 thickness, were cut on a shear about 1½” wide and 4’ long. Each piece was formed on a brake, bending up an edge that was 5/16” wide, and of course these pieces were perfectly straight. But these pieces were formed to the correct radius for both the upper round sign (slight curving radius of about 27”), and the lower sign with corner trim that had an 8” radius. They were hand formed carefully over a scrap piece of plywood cut in a rounded shape that was clamped to the edge of a work table. This part of the job took about a half hour to complete, making plenty of extra retainer pieces just in case.

这个项目的最后部分是使用边条把两个标识的边缘部分做修饰。边条是使用缎银电镀铝做成有.040厚,并用剪刀切成大约1.5英寸宽和4英尺长。每一块边条都使用制动钳塑形,边缘部分弯曲成5/16 宽,当然这些部件都是非常直的。在上面的圆形标识,这些边条部件被弯成正确的弧度(轻微大约27英寸的弧度),和下面标识角的边框将弯成8英寸的弧度。边框都是通过人手在工作台上用胶合板边缘一块一块小心地塑形制作。这部分的工作花了半个小时去完成,并且我们也制作了大量额外的框件以防不时之需。

The retainer pieces were not installed at the shop at all, but were installed around the perimeter of bothsigns only after they were up and faces in place. Final trimming to length was done in the field quite carefully using a decent pair of tin snips. All in all, it was a fun job and the final results more than satisfied everyone at our client’s new office location. No painting or powder coating was done, since all exposed surfaces were pre-finished aluminum, and the clear masking was kept in place until the signs were up.

边框固定件不是在工作室安装,但会在标识表面安装后的周围进行安装。最后会使用铁皮剪在现场对长度进行小心地修剪。所有的一切,证明这是一项有趣的工作。最后的结果,在客户新的办公地点,所有人都非常满意。没有使用喷漆或粉末涂料,因为标识所有外露的表面都是使用经过处理的铝材,并且在标识安装之前都有一层透明的薄膜保护。

My nephew Jeremy and I rode the signs up in our shop’s manlift, but neither sign weighed more than 75 pounds, the top sign weighing less than half that. The signs were lowered down over the existing sign pole to which we had added our pole extension earlier. As mentioned, each sign was tightly secured at its bottom, and had an adjustable bushing at the top, making it very easy to get the signs exactly level and permanently in place with no welding required. Which was just what we wanted, and the signs turned out just the way the client wanted. And, a satisfied customer, of course, is the only kind to have.

我的侄子杰米和我两个人就能把标识运送到安装地点,两个标识没有一个超出75磅重,顶部的标识就连一半的总量都没有。这个标识比早期存在的标识杆低,我已经在之前增加了标识杆的延伸部分。像之前所说,每一个标识都是紧密固定在底部,并且在顶部有一个可调节的套管,使这个标识非常容易地得到水平和永久的位置并且不需要进行任何焊接。这正是我们所希望看到的,而这个标识也是客户想要的。并且,客户的满意是我们唯一的动力。