The University of Pittsburgh in Pennsylvania recently upgraded to new LED display technology and identity-type signage at multiple athletic facilities on its campus—Fitzgerald Field House (volleyball), Ambrose Urbanic Field (soccer), and Petersen Events Center (basketball). The latter venue actually hosts the first collegiate center-hung Daktronics LED video display in the country that features less than 4-millimeter LED line spacing. It also sports a host of creative dimensional components complementing (and adorning) it.

宾夕法尼亚州匹兹堡大学最近为其校园内的多个体育设施:菲茨杰拉德球场(排球)、安布罗斯·厄本菲尔德球场(足球)和彼得森活动中心(篮球),升级了新的LED显示技术和形象标识,而彼得森活动中心是首个于大学场馆安装的悬挂式Daktronics LED显示器,LED行距仅为3.9毫米,此外还预留了许多开放性的创造空间,可以后期进行补充与装饰。

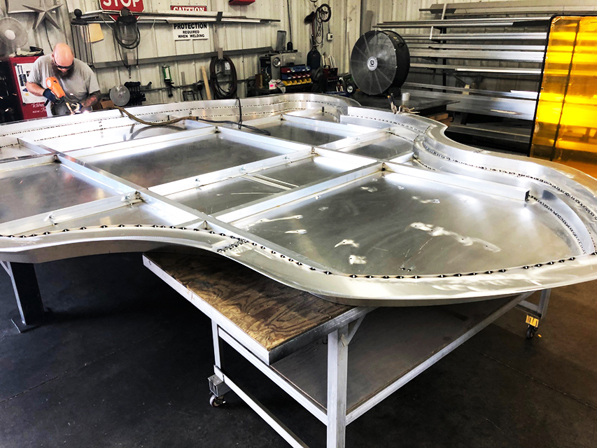

The Petersen Events Center center-hung features four outward-curved LED video displays that are attached to a behind-the-scenes rectangular framework. Each display boasts 3.9-millimeter line spacing, as all four screens combined total eight million LEDs. The sideline-facing displays each measure approximately 15 feet high-by-28 feet wide, while the end-line-facing displays each measure 15 feet high-by-16.5 feet wide. In addition, two end-wall displays inside the facility feature 10-millimeter line spacing and measure 16.5 feet high-by-31 feet wide.

这是一个由四个凸面LED显示器组成,在场馆中心悬挂的大型装置,四面屏幕的背后由一个矩形框架进行连接,LED行距3.9毫米,四个屏幕总计有800万个LED单元,面向球场边线的两个显示屏尺寸为4.5*8.5米,面向球场端线的两个显示屏尺寸为4.5*5米,此外场内的两款端墙显示屏LED行距为10毫米,高5米,宽9.5米。

According to Daktronics Sales Representative Scott Willson, this is actually the fourth center-hung that his company has manufactured and installed at the Petersen Events Center. “Much of the design [for this new project] was selected by the university to fit their specific needs,” he says.

根据Daktronics销售代表斯科特·威尔森的说法,这实际上是他的公司为彼得森活动中心制造和安装的第四台中场设备了,他说:“匹兹堡大学为这个新项目选择了许多设计,从中挑选以符合他们的特定需求。”

The display made its in-action debut this past fall (just in time for the tip-off of the Pitt Panthers basketball season). Content enjoyed by those in attendance includes live video, data and statistics, graphics and animations, and sponsorship messages—all managed as either one large image, multiple zoned images, or data frames through the Daktronics Show Control system.

这四面显示屏于去年秋天首次在比赛中亮相,正好赶上彼特·黑豹篮球季的揭幕战,它们为观众以及选手所带来的内容包括实时视频、实时数据和统计数据,图片、动画以及赞助信息,这些内容全部通过Daktronics展示控制系统处理成一个大的画面,同时进行分区和分帧管理,让人们可以享受信息,沉浸于比赛。

The less-than-4mm line spacing on the center-hung provides significant advantages for how the pictures and images appear on the display. “The tighter pixel spacing brings higher resolution and better image quality to all the content shown on it,” says Willson. “This makes for a better experience for their fans and also a better overall presentation for sponsors. [And] the displays’ dimensions and design provide a unique aspect for the university to connect with their brand and style.”

这面在场中悬挂的巨大显示器,以其不到4毫米的LED行距为显示效果带来了巨大的优势,威尔森说:“更紧密的像素间距可为上面显示的所有内容带来更高的分辨率和更好的图像质量,这位粉丝们提供了更好的体验,也为赞助商提供了更好的整体展示,并且显示器的尺寸和设计将整座大学的品牌与其独特风格融为一体。”

The company in charge of managing the production of the LED display was Masstar Signs, a full-service company out of Greenville, South Carolina. Masstar Signs also ended up doing signage for all three facilities, including vinyl wall and sideline graphics, seven-foot-tall “Pitt” channel letters (located on the bottom of the scoreboard, and an LED internally illuminated panther head logo made from polycarbonate and an aluminum framework. “The Pitt Panther head was our ‘signature mark’ for the entire project. It created a lot of attention and feedback about being a focal point of the project,” says Masstar Signs General Manager Lee Stegall, noting that each of these projects required extensive fabrication and multiple Matthews Paint colors.

负责管理LED显示屏生产的公司是Masstar标识,这是一家位于南卡罗来纳州格林威尔的全方位服务公司,该公司还为匹兹堡大学三个设施进行了其他的标识制作,包括乙烯基墙和侧线图形,高2米的“彼特”发光字,以及由聚碳酸酯和碳纤维制成的LED豹头徽标。

Masstar标识总经理李·斯蒂格尔标识:“彼特·黑豹的豹头标识是我们整个项目的标志物,它为整个项目引起了很多关注和反馈,这些是非常有帮助的。因为这些项目需要大量地调试色彩。”

Over the past twelve years, Masstar Signs has completed multiple signage and iconic branding projects for universities throughout the country. “We excel in custom projects that require significant design and fabrication components, and this [one] included multiple elements,” says Stegall. “So we were confident that our teams would be able to successfully complete this project.”

过去的十二年里,Masstar标识为整个美国的许多大学制作了标识和标志性品牌项目,斯蒂格尔说:“一直以来,我们都擅长需要大量设计和制造组件的定制项目,而这个彼得森活动中心里包含很多元素,因此我相信我们的团队能成功完成。”

Masstar Signs was in charge of evaluating the conceptual drawings of the overall project that were supplied by A/V consultants Anthony James Partners of Richmond, Virginia. “Our goal is to take the consultant’s conceptual ideas and ‘fabricate them into life’ for a successful installation,” says Stegall. “The conceptual drawings provided to us were impressive and well thought out.”

Masstar标识负责考量与完善整个项目的概念图,该图有弗吉尼亚州里士满市的顾问安东尼·詹姆斯提供,斯蒂格尔说:“我们的目标是将顾问的概念性想法切实融入进项目,以使其成功安装。当然,原版的概念图也是经过深思熟虑才创作出来的,令人印象深刻。”

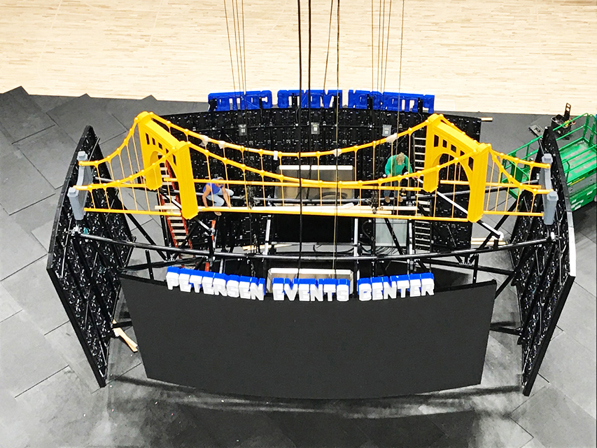

As mentioned earlier, the new LED video display was but one item of these athletic facility upgrades. Each of the accompanying projects’ elements at the three venues features something either significant to the city of Pittsburgh landscape or unique to the University of Pittsburgh. For Petersen Events Center, the conceptual drawings for the LED display included one of the nearby Three Rivers bridges atop it.

正如之前所说,新的LED显示屏只是这些体育设施升级中的一项,这三个体育设施的每个改造项目都将匹兹堡市的景观或匹兹堡大学具有独特意义的场景融入其中,在彼得森活动中心,LED显示屏的概念图顶部,就有一座著名的三河大桥。

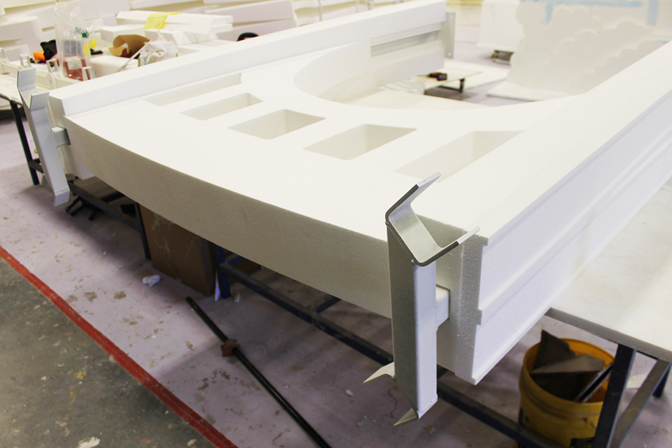

Measuring roughly seven feet tall and thirty-eight feet in length, the cabled bridge rests in between all four Daktronics screens above the main structure. It was important that this bridge element needed to be lightweight so as to not weigh down the massive new display, which meant foam-core material would prove the opportune choice here.

缆绳桥架高约2米,长11.5米,位于主体结构即四块屏幕之间,这就要求桥梁模型的组件比去非常轻巧,否则增加太多重量,原先的承重可能不能担负,幸好有泡沫芯这种超轻材料可以作为最佳选择。

With this in mind, Masstar Signs sought out foam-core monument provider Signs By Benchmark of Watertown, South Dakota to complete this decorative sculpture atop the center-hung scoreboard. Stegall had first met the company years ago at ISA International Sign Expo and followed up with various Web-based conversations.

为此,Masstar标识找到南达科他州沃特敦著名的泡沫芯供应商Benchmark来完成位于悬挂式显示屏顶部三河大桥的装饰雕塑,斯蒂格尔多年前在ISA展会上首次见到该公司,随后一直在网上保持联系。

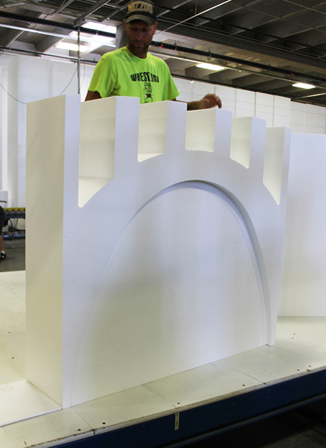

Masstar Signs supplied Signs By Benchmark with the provided conceptual drawings. “From there, we used photos of the actual bridges to create our drawings and be as true to the original concept as possible,” says Signs By Benchmark Senior Designer Jamie Kakacek, noting that they shared all the drawings they created with the involved groups prior to starting any actual fabrication.

Benchmark公司的高级设计师杰米·卡卡茄科说:“Masstar标识提供了概念图,然后我们据此开始创建蓝图,并尽可能地符合原始概念。我们与该项目的其他小组进行了共享图纸,以便于实际的制造。”

Kakacek reports that the Daktronics screens didn’t really affect the pieces they were responsible for producing. “We did, however, have to be cognizant of the structure underneath so we could anchor the foam-core bridge to the central frame,” he says.

卡卡茄科的报告指出:Daktronics屏幕实际上对他们的桥梁模型生产并没有影响,但是必须了解下面的结构,才好将泡沫芯的桥固定在中央框架上。

The bridge was made from a combination of foam and steel. “The versatility of our foam-core products lends itself well for the major gateway pieces, but certain elements, such as the cabling system were not suitable for creating out of foam,” says Kakacek. “We used lighter weight materials in the foam and metal, including aluminum, so we wouldn’t be adding too much strain to the display.”

整座桥梁使用泡沫和钢制作,卡卡茄科说:“我们的泡沫芯产品的多功能性非常适合主体部件,但某些特殊部位不适合用泡沫制作,所以我们在其中加入了重量比较轻的金属材料,比如铝、不锈钢等,因此不会给显示器太大的压力。”

The two main five-foot-wide gateways were cut to shape using a combination of CNC hot wire cutting equipment and a CNC router. The steel cable system connecting the gateways was made with a combination of a CNC router and a laser, as well as a break for the metal brackets. Mounting hardware was concealed below the bridge deck or inside end pylons and was not visible on the face end of the pieces.

使用数控剪钳与数控切割机的组合,将两面1.5米的桥拱切成需要的形状,连接桥拱的钢缆则是数控点科技和激光制作。安装固定的硬件完美隐藏在桥面板下方或内部定向塔中,保持表面的完整性和一体性。

As mentioned earlier, weight played a big concern for the bridge structure; because of this, Signs By Benchmark fabricated the core of the bridge out of one-pound-density expanded polystyrene (EPS) foam. “Had this been in an area that was more susceptible to damage, we may have chosen a higher density material to give it a bit more strength,” says Kakacek. “But aside from the occasional cleaning, there really shouldn’t be much reason for these to be touched for the foreseeable future.”

正如前面所说,重量是这个桥梁结构最主要的问题,因此Benchmark用了一磅密度的发泡聚苯乙烯泡沫制造了桥芯,卡卡茄科说:“如果这个区域更容易受到损坏,我们可以选择更高密度的材料,使其强度更高,但经过了解,在可预见的将来,除了偶尔的清洁外,这个部位应该没有被太多被触碰到的机会。”

After assembly, Signs By Benchmark encapsulated all the foam parts in their polyurea hard coat system to give everything the necessary strength.

组装后,Benchmark将所有的泡沫部件封装在硬涂层系统中,以赋予其所必要的强度。

The bridge was constructed entirely on the floor of Signs By Benchmark’s shop. “We then broke everything down for painting,” says Kakacek. “The bridge shipped out as ten separate pieces on a dedicated truck where they could be picked up on site and installed onto the framework.

这座桥的制作全部在Benchmark公司的地板上完成,卡卡茄科说:“制作完成后,我们将所有的东西分解并绘制组装图,然后分为十个单独的零件放在专用卡车上运出,到现场后可以轻松拿起并安装在框架上。”

“We built cradles for the cables to ride in, which would also serve as pick points for installing the bridge. The joints where the cables bolt to the gateway pieces also doubled as pick points for lifting each section onto the frame.”

Benchmark钢缆制作了支架,这些支架也可以用作安装桥梁的接点,钢缆螺栓在桥拱上的固定接头同样可以作为安装至框架上的接点使用,构造非常巧妙。

Two other companies worked on the installation. While Masstar Signs did not handle this actual installation, they did go to the site for part of the installation and work closely with the install crews.

另外两家公司也从事安装工作,尽管Masstar标识无法处理这些安装的实际操作,但他们也尽力与安装人员紧密配合,帮助了现场部分安装的进行。

The massive screen structure was lowered down to the ground level. After getting each bridge section lifted into place and maneuvered around the framework, the foam-core structure simply bolted to the frame provided by Daktronics. “No other specialty equipment was necessary,” says Kakacek.

在安装桥梁模型时,将巨大的LED屏幕结构降到了地面,在将每个桥梁部件放在相应的位置上拼接起来之后,泡沫芯结构只需用螺栓固定到Daktronics提供的框架上,而无需其他专业设备。

Everything on the display is tied to eight main steel support posts that support the entire load. “Each gateway section houses two support poles with match plates that marry up with the Daktronics-provided framework,” says Kakacek.

显示屏上的所有东西都与8个钢支撑柱相连接,这些支撑柱职称着整个结构的负载,卡卡茄科说:“每个桥拱部分都包含两个支撑杆,支撑杆上带有能够与Daktronics的显示屏框架相匹配的匹配板。”

Also attached to the framework supporting the Daktronics LED display screens were venue ID channel letters at the top and “Pitt” channel letters on the underbelly. Masstar Signs used different shades of Matthews Paints to bring these components to life. (Note: The bridge body was painted using PMS Gold 1235C gloss enamel and the end pylons PMS GG10 satin.)

支撑LED显示屏的框架还附加了:彼得森场馆名称和“彼特”字样的发光字,Masstar标识使用了不同颜色的喷漆使这些组件栩栩如生,在桥梁部分,桥身使用PMS金色光泽搪瓷漆,而塔架则采用PMS缎面涂漆。

The University requested a very tight timeline to complete this project, yet all parties rose to the challenge in meeting this ticking clock. “We always try to meet the needs of our customers and worked around their existing practice and game schedules to deliver their product,” says Willson.

匹兹堡大学所规定的完成时间表非常紧迫,于是所有合作的公司都面临紧迫工作时间的挑战,Daktronics的威尔森说:“我们一直努力满足客户的需求,并会按照他们的工作惯例和时间表来交付他们的产品。”

Kakaceck reflects that this project took his company a bit out of their normal comfort zone in terms of materials that were used and how to properly tie each piece together. “However, through close collaboration with Masstar Signs, I think we managed to work through any topic of discussion pretty easily and quickly,” he says.

卡卡茄科则表示:“这个项目使我的公司从确定使用材料,到正确制造部件以及安装的方面都有些忙乱,但是通过与Masstar标识的密切合作,我认为我们还是轻松、快速地完成了所有既定的产品主题。”

Pitt Director of Athletics Heather Lyke, in a prior released press announcement, said, “Thanks to a great partnership with Pitt Sports Marketing and our JMI Sports team, we have installed video boards that should help us create one of the best in-venue viewing experiences in all of college basketball. Our commitment to enhancing the game-day experience for our fans is absolutely being realized.”

彼特田径运动主管希瑟·莱克发布的新闻公告中说:“由于表示彼特体育营销和我们的JMI体育团队建立了良好的合作关系,我们为其安装了显示面板,这个面板可以将彼得森活动中心打造成所有大学的篮球比赛中,具有最佳场内观看效果的场馆之一···而我们答应粉丝们会帮助你们提升观赛体验的承诺,现在也已经实现了。”

Stegall credits his in-shop team and how their approach works well on complex projects. “This project included three venues, each with elements all being built at the same time, in addition to other projects that were being manufactured at our facility during this timeframe,” he says. “Multiple meetings with our design, project management, and fabrication teams were required so that the project could maintain its timeline.”

斯蒂格尔赞扬了他的公司团队以及他们在复杂项目的运作中极富效率的工作方法,他说:“整个项目包括三个地点,每个地点都需要同时建造,而我们的工厂还要加工其他项目的材料,于是我们的设计、项目管理和制造团队召开了多次会议,帮助项目能在规定时间内完成。”

In the end, Stegall says that the consultants, engineers, project managers, and installers made this project a success from the initial vision through design, build, and installation. “The [Pitt Panthers] project is a great example of how communication, teamwork, and execution with a tremendous amount of planning equals a successful project that provides the end-customer a showcase environment for years to come,” he says.

最后,斯蒂格尔说:“顾问、工程师、项目经理和安装人员的努力使该项目从最初的构想到设计,再到建造和安装,每一步都取得了成功,其中“彼特”豹头徽标是一个很好的例子,它代表了‘大量的沟通、团队的合作与执行’就可以完成一个成功的项目,而这个豹头徽标也为客户提供了在未来数年都会被人津津乐道的展示环境。”

One can easily say that this fast-break project ended up being slam dunk for all the parties involved. Their end-creation is an experience that Petersen Events Center guest can soak in and enjoy.

毫不夸大的说,这个“快攻”般的项目,无论在哪个环节都属于“灌篮高手”的级别,他们通力合作,创造的不仅是崭新的设备和环境,更是每一个进入到彼得森活动中心的客人们所享受的体验。