In all computer numerical control (CNC) routing applications, from hobbyists’ one-time projects to mass production lines, the bit selected for the job can make an enormous difference to the results. Choosing the right option can be confusing, but making the optimal decision is worthwhile, as it will help cut down on waste and material costs. Moreover, CNC bits—which range from solid carbide to steel, cobalt-chromium and diamond-tipped edges—directly determine the quality of the final product.

在数控切割机(CNC)的应用中,无论是业余爱好者的一次性项目还是批量生产的流水线,为工作选择的切割钻头将会对最终的产品结果产生重要的影响。如何做出正确的选择有时的确会让人产生困惑,但是最佳决策的制定还是十分必要的,因为这有助于减少浪费和节约材料成本。此外,CNC设备所使用的钻头(硬质合金、钢材、钴铬合金和金刚石材料)将直接决定最终产品的质量。

Applications and materials

应用和材料

Of course, the type of material to be cut will heavily inform the selection of CNC bit. Some sign shops use a router specifically for wood, while others process larger quantities of plastics, acrylics or aluminum. There are certainly many choices of materials that can be cut with the same router.

为CNC切割设备选择合适的钻头时可以根据需要切割的材料来判断。一些标识商店在切割木材时会使用专用的切割钻头,而在处理其他材料时则会根据需要选择塑料、亚克力或者是铝制钻头进行切割。当然,很多材料也可以使用相同的切割钻头进行切割。

While a router may be highly versatile, a ‘one size fits all’ approach does not apply to bit selection. If the wrong bit is chosen for the given material, the cutting process may destroy the bit or, in the worst-case scenario, the machine itself. One goal to keep in mind is to cut the material without grinding it.

虽然切割设备具有普遍的通用性,但“一刀切”的方法显然不适合所有的材料。如果为切割材料选择了错误的切割钻头,那么在切割过程中,轻则钻头损坏,重则设备本身损坏。切割工作的原则是在不耗损材料的情况下进行切割。

For some materials, multiple bit types can be used, while for others, there is only one preferred option. When cutting aluminum, for example, V-bits, ball-nose bits, upcut end mills and O-flutes will all clear chips of the material away, preventing them from fusing to the bit at very high operating temperatures. When cutting plywood or melamine, on the other hand, it is best to use a compression bit, which will avoid chipping or tearing the material.

有一些材料可以使用多种切割钻头进行切割,而另外一些材料的最佳切割钻头只有一种。在切割铝材时,选择V型钻头、球型钻头、上切端铣刀或O型槽钻头都可以很方便地对切割材料时产生的碎屑进行清理,但是需要注意的是避免材料在极高温的情况下工作,不然材料的熔化会干扰钻头的正常运作。另一方面,当切割胶合板或双饰面板时,最好使用可压缩钻头,这样可以避免碎屑的产生或材料的碎裂。

The most versatile bits, which may be suitable for shops that are new to CNC routing or signmakers who simply prefer a multi-purpose approach, are probably two-flute spiral bits, which can be used to cut wood, foam, plastics and aluminum.

对于那些不熟悉CNC切割设备的标识商店或只喜欢多功能切割设备的标识制造商来说,最通用的钻头就要数双槽螺旋钻头了,这种钻头可用于切割木材、泡沫、塑料和铝材。

Speed vs. Finish

速度与成品

Some projects need to be completed as quickly as possible. For others, the smoothness of the cuts is the top priority.

尽管有时的项目需要早日完成,但是大部分情况下,保持切割设备在工作时的平稳性才是首要任务。

As such, the type of bit to be used at a specific stage of processing will depend largely on whether speed or accuracy is the most important consideration. Upcut end-mill bits, for example, are ideal for quick, straight cuts and deeper holes where chip evacuation is key, but can negatively affect the quality of the finish by fraying fibres. Ball-nose bits will achieve the best results when carving intricately detailed designs; they are used for two- and three-dimensional (2-D and 3-D) profiling and carving of wood, aluminum and plastics and their rounded edges are designed to cut smooth contours.

因此,在处理特殊情况时将设备的切割速度或是切割准确率作为最重要的考虑因素时,将很大程度上决定选择的钻头类型。例如,上切端铣刀在高速切割、直线切割和深孔切割的碎屑排放方面对于设备的理想选择起到了关键性的作用,但是经过磨损的纤维会对成品质量造成负面影响。切割纹路较为复杂的设计材料时,球型钻头将切割出最佳效果,当它用于切割木材、铝和塑料材料的平面或是进行立体的断面切割和雕刻时,这种钻头的圆形边缘可以切割出光滑的轮廓。

The speed of a cutting feed will vary, depending on a few factors, including the following:

以下几点因素对于设备的切割速度均会产生影响:

The horsepower of the spindle.

主轴的功率。

The strength of the clamps or vacuum table holding the panels down.

固定面板的夹具或真空吸附台的强度。

The overall stability of the CNC router.

CNC切割设备的整体稳定性。

The condition of the collet (i.e. the band around the spindle).

夹头的状态(即主轴周围的绑带)。

Cutting at a high rate right from the start can make it difficult to gauge the optimal speed. Instead, it is preferable to initially cut the material at a lower rate and then gradually increase the speed and feed, all the way up until the point where the quality of the finish starts to become unacceptable.

如果一开始就使切割设备高速运转反而难以测量设备的最佳速度。相反,正确的做法是首先以较低的速度对材料进行切割,然后逐渐增加切割速度和切割材料数量,一直到CNC切割设备难以保质保量地完成材料的切割工作时,此时就可得出设备的最佳速度。

Speed factors into determining the correct diameter and size for the bit, through the context of its ‘chip load.’ Chip load can be only be calculated if the user knows the router’s feed rate—i.e. how fast a material will move through the machine, commonly measured in inches per minute—along with the bit’s speed in terms of revolutions per minute (RPM) and its number of flutes.

在对打印机的“芯片负载”能力稍作了解之后,速度系数会影响为钻头选择合适的直径和尺寸。如果用户已知切割机的进给速率,那么就可以对切割机的芯片负载进行计算。材料在机器中移动的速度通常以英寸/每分钟来表示,每分钟转数(RPM)和凹槽数量也会影响钻头速度。

The formula for this calculation is as follows: chip load = feed rate / (RPM x number of flutes)

该计算公式如下:芯片负载=进给速率/(RPM×凹槽数量)

It is important to keep in mind chips that are too large can break the router bit, while chips that are too small can turn waste into powder and dull the bit. So, it is very worthwhile to choose the right diameter and size of bit based on the chip load, as those factors will in turn affect the size of the chips.

需要记住的是,芯片负载过大会破坏切割机的钻头,而芯片负载过小则会将废弃的材料直接变成粉末并使钻头变钝。因此,根据芯片负载来选择合适的钻头直径和尺寸是非常重要的,因为这些因素反过来也会影响对芯片负载的考量。

That said, since the calculation of chip load is only based on an average thickness of material for a given cutting tool, it is just a starting point. So too are the tool vendor’s recommended settings. Ultimately, it is up to the machine operator to establish the proper settings for the sign shop’s applications, which will involve a process of trial and error.

也就是说,由于芯片负载的计算以给定的切削材料的平均厚度为基础,因此这只是最基础的一点,工具供应商也可以根据以上条件对设备设置提出建议。最终,由切割机操作员为标识商店的应用程序调控合适的设置,在设置的过程中将不断地进行反复试验。

As for the finish, the more flutes on the bit, generally, the higher the quality of the cut. Users can choose from one-, two-, three- and four-edged flutes on their CNC routing bits. The two- and three-flute bits may suffice when the quality of the finish is important, while the four-flute bits will provide the highest level of detail in their cuts. Ball-nose bits are an excellent option for designs that involve intricate components.

至于对材料表面的处理,钻头上的凹槽越多,通常切割出来的材料也越优质。用户在使用CNC切割机时,可以选择带有一个、两个、三个或是四个凹槽的钻头进行工作。如果想重视材料精加工的质量时,那么双槽或三槽的钻头就足够了,使用四槽的钻头可以在切割材料时提供最高水平的细节处理。当涉及复杂材料的切割时,球型钻头将是一个很好的选择。

V bits are great for signmaking in general, They can cut decorative letters and grooves. They are relatively inexpensive and can cut aluminum composite materials (ACMs), medium-density fibreboard (MDF), high-density urethane (HDU) foam boards, metals and fabrics.

标识制作商大多数都会使用带有V型钻头的切割机,这种切割机非常适合用于切割艺术字母标识和凹槽。这种切割机相对便宜并且可以用于切割铝复合材料(ACM)、中密度纤维板(MDF)、高密度聚氨酯(HDU)泡沫板、金属和织物材料。

Cutting direction

切割的方向控制

In addition to selecting the router bit based on the material to be cut, it is essential to take the primary cutting direction—i.e. up or down—into account, so as to avoid damaging the material.

除了根据切割的材料来选择切割机的钻头之外,确定切割机的切割方向也很重要,为了避免造成材料的损坏,在机器开启之前必须确认好材料的切割方向。

Upcut bits, as their name suggests, are beneficial because they pull the chips up and away from the material, but they will splinter plywood and melamine. Meanwhile, downcut bits, which press waste back into the cut, are great for cutting aluminum, but will melt plastics. This is because not allowing the chips to escape will create friction and, thus, a buildup of heat. A downcut endmill bit is suitable for slower feed rates and cutting shallower holes, where the finish is key.

上切钻头往往是切割机的优质之选,因为这种钻头在进行切割时会将切屑向上拉离材料,但它们会导致胶合板和双饰面板的碎裂。与此同时,将废料压回切口的切割钻头非常适合用于切割铝材,但用于切割塑料时,会导致塑料的熔化,原因是控制碎屑的排放容易导致材料表面产生摩擦,进而导致热量的聚集。下切端铣刀适用于切割速度较慢的设备和用于浅孔的切割。材料的表面材质将会对钻头切割方向的选择起到关键性的作用。

Compression bits cut both up and down. They are generally a little more expensive, but provide a useful multi-purpose option for routing wood and, especially, plywood.

同时进行向上和向下切割的设备通常购买费用比较贵,但是在对木材和胶合板进行切割时能够起到非常大的作用。

Other considerations

其他注意事项

When purchasing a bit in the first place, there are several other factors worthy of attention, to ensure the sign shop gets the ‘biggest bang for the buck.’ Durability and performance, for example, are important to look into before making a significant investment in the technology.

在购买设备时,还有一些重要因素值得关注,以确保标识商店在最大程度上获得收益。例如,在进行重大投资之前,关注设备的耐用性和性能就非常重要。

Sharper bits provide clean cuts and will allow the machine to run quieter and use less power.

钻头越锋利,切割出来的材料越是干净利落,并且设备在运行时产生的噪音也越低,耗电越少。

Shorter bits will also usually provide cleaner cuts, whereas longer bits tend to increase the degree of vibration, potentially causing the bit to bend. A larger shank diameter on the bit, meanwhile, will result in cleaner cuts and prove more durable.

长度较短的钻头越是能提供利落的切割操作,而较长的钻头在工作时则往往会增加本身的振动频率从而导致钻头的弯曲。同时,钻头上方的柄部直径越大,切割越干净,越耐用。

The longevity of CNC bits also depends on operators taking good care of them. This includes proper storage (e.g. in a dedicated ‘tool library’) and keeping them sharpened as needed. Cut consistency can also be ensured by always warming up the spindle prior to routing.

CNC切割钻头的使用寿命也取决于工作人员如何维护它们。比如周期性地将钻头保存在专用的工具库中,并根据需要对钻头进行锐化处理。在进行材料切割之前,先将主轴预热,也可以保证切割过程的稳定性。

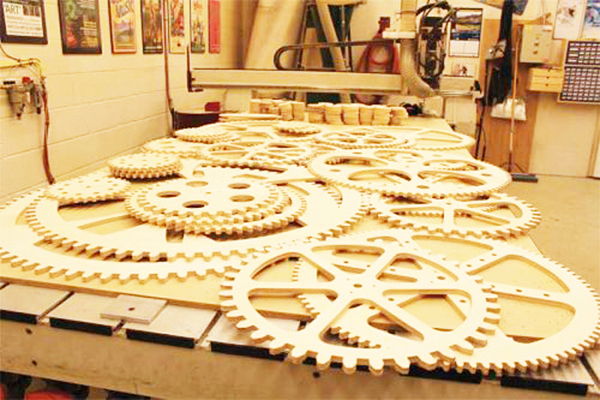

Once a sign shop has mastered the basics of CNC routing, highly specialized bits are also available for such purposes as boring holes, surfacing large panels, cutting miter folds (i.e. notches for angled folds) or routing frames for graphics. Indeed, with today’s range of CNC bits, a router can fabricate almost anything a signmaker might design.

一旦标识商店掌握了CNC切割设备的基础知识,高精度的钻头也可用于诸如钻孔、大型板材的表面切割、斜角折叠切割(即用于切割以一定角度折叠的凹槽)或塑造图形切割框架等目的。实际上,如今市面上出现的所有CNC钻头系列,几乎可以帮助任何标识制造商使用切割机来完成设计产品的制作。